Leaderboard

Popular Content

Showing content with the highest reputation since 07/12/2025 in all areas

-

A couple of months ago I did a little report on the Henry .327 rifle. After a tune-up and throwing away some parts I was, and continue to be, amazed at how well it works. I prefer tuned 73s with short strokes and remembered I had converted a Ubert 73 rifle to .32 about 20 years ago. It ran but not as well as I hoped so I dismantled it and used some of the parts in another project. I decided to dig out the barrel and some other parts and try again. Unfortunately I had cut off the chamber area so I would have to cut new threads on the barrel. I had sold my old lathe and only have an 80 year old 9" Logan right now. I immediately had a problem as the barrel was a little too big for the through hole in the headstock. I had to shorten the barrel to 16 1/2" to get it to fit into a four jaw chuck and a dead center mounted in the tailstock. It just barely fit. Lots of parts had to be modified or made new. Here is a photo showing some of the parts. Starting at the top. The dovetail for the fore end cap had to be recut 3" forward. The chamber section I had cut off the original experimental .32 barrel 20 years ago. (Why I did this I cannot remember.) An adapter to go from a Uberti mag tube down to an old Marlin mag tube. The bolt had to be modified. A new follower made. The shortened barrel with new threads. The rear sight dovetail had to be moved forward and the old one filled. The carrier had to have a piece of brass tube soldered in and machined to .32 size. It also had to be shortened. The Marlin mag tube and a piece of Uberti tube beneath it. The bolt had to be turned down and the extractor and bottom tab moved to fit the .32. .357 bolt on the left, .32 on the right. The 20 year old carrier shortened compared to a stock carrier. A piece of Uberti tube was green loctited to the Marlin tube to fit the barrel hanger. A spacer had to be machined to take up the space left by the shortened carrier. The finished rifle. It seems to cycle fine and the 16 1/2" barrel actually makes for a well balanced rifle. I am gathering parts to build a second 73 but using a carbine barrel to lighten it a bit.19 points

-

16 points

-

12 points

-

12 points

-

11 points

-

11 points

-

11 points

-

Everyone knows how much I preach about supporting the merchants who support our game. It’s on each of us to spend a little with them. You might think you don’t need a new vest or more loading supplies — but trust me, you need them more than you realize. Without their support, our matches would struggle. In June, I shot the Regulators Reckoning at Wartrace, and Michigan Rattler was a match sponsor. My gun belt was cinched to the smallest hole, and I needed new leather (again) after losing a lot of weight. Naturally, I reached out to Michigan Rattler and commissioned a dress belt (for everyday wear and my Frontiersman buckle), a new shotgun belt, and a new gun belt. The new leather arrived today, and it’s exceptional — top-notch quality and craftsmanship. I’ll be shooting with the new gear this weekend and will report back on just how much faster his leather is than anyone else’s! Big thanks to Michigan Rattler for supporting our game, and the outstanding products and exceptional service — all at a fair price!10 points

-

If this isn't the right place please delete or move. Thanks I just wanted to share my experience with the Hat Rack Guy. I bought his 9 hat rack for my office where I keep all my cowboy hats. What I got was a great product that keeps my hats safe and secure. I could not be more pleased with the rack. It worked so well I also bought a 2 hat RV rack for my 5th wheel so when traveling to matches I have a safe and secure place to put a couple of hats. https://www.thehatrackguy.com/?syclid=f0a23468-9abd-4ab6-9e4c-84375b6a8712 TM10 points

-

10 points

-

10 points

-

Natchez has free Hazmat today and tomorrow (July 17-18), Code FH250717, and most Federal primers are $59/K. https://www.natchezss.com/reloading/primers/pistol-primers9 points

-

Free ammo for life? 80,000 rounds? I’ll pass. I plan to live past 2027.9 points

-

The Friendliest Bar In Town A WEEK HAS SEVEN DAYS. Everyone knows this. Even the hard-working, hard-studying, totally serious lads of Kappa Phi Delta. Heck… maybe especially the hard-working, hard-studying, totally serious lads of Kappa Phi Delta. And the five day period that comprised the middle part of the week, that part that separated the glorious weekends, was an especially long stretch of devotion to our labors. And so it came to pass, either by committee proclamation, idea-osmosis, or just plain old desperation, that a determination was made that it would be in our best interests – physical, mental, and emotional – to divide this stretch of time into manageable sections. And fortunately, with thanks to Julius Caesar and his invention of the modern calendar in 46 B. C., the five-day stretch separating weekends was quite handily broken up by that most marvelous middle day, Wednesday! (Thank you, Odin!) So, after supper and any homework that couldn’t be put off, but usually no later than 2100 (that’s nine o’clock PM), several of us would saddle up and head out to visit a known establishment, like “The Front Room” pizza parlor or “The John Barleycorn,” just around the corner. Or, if the mood struck, perhaps search out a new watering hole. And we found a few! “The Griffin,” where we were always welcomed (after the women realized we weren’t going to steal their girlfriends) and where we rescued and returned a wounded (but well anesthetized!) sergeant to Letterman Hospital, “The Cock’s Inn,” with the giant neon rooster over the door and where said sergeant dominoed several bar stools, depositing their residents onto the floor. And others. On one particular Wednesday in ‘71, Hank, Bill “Wynuts” Wyant, Louis Quint, myself, and one or two others were packed into Hank’s ’62 T-bird. We were on the prowl. We expected to end up at one of the “established” establishments, and were headed up California Street when someone said, “Look!” Of course, we all looked where someone pointed. And there, was a simple but well-illuminated marquee, declaring the place to be “The 998 Club ~ The Friendliest Bar in Town!” Well, Goll-ee! How could we go wrong with a place posting such a proclamation? “Uh…Hank…?” “Yeah Man! I see it! I’ll find us a parking place!” He did, only a half block away, fortunately downhill from our target. Fortunately, because, although the hike up California Street was fairly steep, we would have gravity on our side when it came time to stagger back to our ride. I’ll be dinged, but the marquee was truthful! We thoroughly enjoyed the next several hours. The staff was friendly, polite, and prompt with service; the other clients were likewise friendly. Good conversations about sports, a few games of dice (Liar’s Dice, Ship-Captain-Crew, and the like), darts, some light-hearted flirting, and general jocularity. A note about the staff! Wynuts, Hank, and I were sitting at a small round table next to a plate-glass window, watching traffic – foot and auto – outside, enjoying our libations and all-in-all having a good time. But at one point, Hank made an exaggerated gesture and swept his drink glass off the edge of the table. Crash! And remarkably, in an instant a young serving lass had the glass, ice, and liquid cleaned up – and a fresh drink on the table. With a smile and no charge! And all was well, until a few minutes later, most amazingly, Hank repeated the move with the same result! And again, remarkably, in an instant that young lady repeated the service, this time with an amused giggle. No one knows why; full moon? Odd conjunction of other planets? Poltergeists? No telling. But, even more remarkably, Hank managed to send THREE MORE GLASSES crashing to the floor! Starting with drink number three, “Miss Brandy” decided to just leave the rubble on the floor. “Watch your step!” she’d say, still with a smile, as she’d plop a fresh glass in front of Hank. At least six drinks were served to the lad that night. But with most of ‘em puddled on the floor, he was sober as a judge when we returned to the frat house. Consequently, “The 998 Club” continued to be a favored spot for a few Wednesdays. Until one… well… one somewhat of a quirky mid-week expedition. On this particular Wednesday, for some reason I was not part of the “break-up-the-week” crew. Actually, I think I was working the swing shift at my mailroom job, and didn’t get home ‘til after midnight. For me it was a quick snack, and off to bed for some sound sleep. Until about 0330. What a racket! The revelers returned, definitely not in “silence mode.” Naturally, I had to bail out of bed to get the story. There HAD to be a story. And there was! And after hearing the story, I must say that to this day I am appreciative of having worked that night. Much safer. It seems that the fellas – “the usual gang of suspects,” with the addition of John “JJ” Jarvis – had set out in earnest to break up the week. And they were quite successful! The “John Barleycorn,” another dive by the waterfront, food at some time during the evening, and then someone realized that “Last Call!” was imminent at whatever pub or tavern they were at. Well, evidently, someone then offered up the observation that if they REALLY hurried, they could make it to The 998 Club in time for THEIR “Last Call.” A good idea, perhaps, but not well thought out and certainly not practical. Of course, those two factors were never an impediment to the men of Kappa Phi Delta! And with that, the fellas rushed out of whatever establishment they were in and dashed the few short blocks to the “998.” Alas, the best laid plans and all that, they were too late. Lights were on, a few souls could be seen milling about inside, but the door was locked. Well, shucks. Now what? Naturally, the proper and logical thing to do would be to saddle up and head home – after all, Thursday would be back to jobs and school, and so some sleep would be beneficial. Uh… nope. ‘Tain’t gonna happen. Not with these fellas! All wired up, or as my dear ol’ grandma would’ve said, “full o’ piss and vinegar.” Could NOT call it a wrap just yet – nosiree Bob! Hank wasn’t driving this night; but he was sitting in the “shotgun” seat of whoever’s car they were in, alternating between snoozing and sipping off his ever-present flask of Old Crow stashed in his vest pocket. Bill “Wynuts” and Louis decided to hike up the street a block or two, just on the off chance that some other place might still be open. But JJ had another idea! In the trunk of the car was a set of golf clubs. And, naturally, in the golf bag were quite a few tees and golf balls. And they just happened to be near the crest of California Street. Hmmm… So, without further ado, JJ selected a nice driver, stuffed a few tees and a bunch of golf balls into a pocket, and set off. Finding a likely spot, he discovered that he could press a tee into the slight gap between the pavement and the cable car track. And what a perfect place to drive balls from! We never did hear if that dozen balls sent flying off into the night did any damage (fortunately, it was late enough that personal injuries were unlikely), but he later proclaimed that he’d achieved tremendous loft and incredible distance! “Dang! I’m sure I got over four hundred yards! Heck, it was so far I couldn’t even hear ‘em hit!” At some point, Hank woke up and realized he was alone. Of course, he didn’t realize that Wynuts and Louis were on a walkabout and Jarvis was playing Arnie Palmer; he quite naturally assumed they were practicing twelve-ounce curls inside the 998 Club. So, not wanting to be left out, he decided to join ‘em. And was quite surprised to find the door locked. Shoving and rattling the knobs did nothing. “Lemme in!” he finally shouted. “We’re closed!” came a muffled reply from inside. “Lemme in!” he demanded. “We’re closed!” was repeated. By now, ol’ Hank was getting kinda frustrated. He just KNEW that his pards were inside, enjoying “Last Call” while he was locked out. “Dang-Blast It! LET ME IN afore I gits my shotgun and BLOWS my way in!” he blustered. This time, there was no response. Accepting that he was not going to gain access – and having no shotgun – he wisely decided to return to the car, crawl in, sip a bit more whiskey and perhaps snooze until the fellas came out and joined him. Meanwhile, Bill and Louis were likewise headed back to the car, where they met JJ. John stowed the golf club in the trunk, and led the others to a vantage point where he could boast of his deed. Of course, none of them could have known that the righteously alarmed proprietor of the 998 Club had in a panic called the SFPD. And the noble and gallant Men in Blue responded with alacrity! Hank was awakened from his slumber by the somewhat noisy and garishly illuminated arrival of two carloads of San Francisco’s Finest, accompanied by an official conveyance colloquially known as a “Paddy Wagon.” With some amazement, he watched as the enthusiastic officers descended on his three astonished and confused comrades. He slid down in his seat, barely peeking over the dashboard, and watched as the fellas were frisked, handcuffed, and unceremoniously shoved into the back of the boxy van-like truck. Instantly sobered up, he decided to move to the driver’s seat – the key was still in the ignition – and follow at a discreet distance, perhaps to render aid to the guys if possible. Well, as luck would have it, it seems that JJ and Bill both happened to know one of the two officers manning the paddy wagon. In fact, they all thought the situation was somewhat hilarious – but they were still going to haul ‘em to the station. ‘Twas protocol, don’tcha know. Once installed in the vehicle, the frat guys discovered they were not alone; there were three or four other drunks, who were themselves quite intrigued by the recent arrivals. And, being Kappa Phi Delta men, our erstwhile heroes were not about to go quietly. ‘Specially since one of their “captors” happened to be a buddy. So, after a quick discussion, they formed a plan – to wit, the three of ‘em started shouting, “Police brutality! Help! Help! Police Brutality!” and began rocking the wagon from side to side. And hollered the louder! Not to be outdone, the officers in front decided to reciprocate by swerving the wagon as violently as they could without toppling the tall vehicle or crashing into something – tree, curb, cars… By the time the wagon approached the police station, the other drunks had all gotten into the spirit of the event and they had a regular chorus going. “Police Brutality! Police Brutality! Pigs! Pigs! Pigs! Sooo-eeee! Sooo-eeee! Sooo-eeee!” repeated again and again, with the prisoners all swaying in unison. When the vehicle arrived at the station, the other officers on duty were surprised to see their comrades exit the front, laughing uproariously, with a drunken choir cheerfully and exuberantly providing an unexpected but loud and melodic chant which, although offensive in words, was in reality terrific comedy. Especially with the one extremely gay drunk singing in a tinkling falsetto. Well, all in all, it was a good-natured “arrest.” It was ultimately established that none of the fellas in capture had grumbled the threat at the door of the 998 Club; indeed, it was decided that everyone hauled in would be released if they could find transportation. And, of course, in short order Hank arrived – with no one the wiser of him being the catalyst of the evening’s topper. Sadly, though, we all felt it prudent to scratch the 998 Club off our Wednesday list. And that was too bad, really… ‘cuz, on balance, it truly was “The Friendliest Bar in Town!”9 points

-

9 points

-

9 points

-

9 points

-

A co-worker moved from South Dakota, where she had lived for most of her adult life, to NC. The move was in February. Come spring the allergies set in. She was miserable and had trouble breathing. I told her, "You're being exposed to allergens (pollen) that you never have been before. Find some place that sells LOCAL, RAW honey. Eat a spoonful every day." She did. All cleared up in two weeks. I think she's still doing it. Given how miserable she was, she's probably afraid to stop. Raw honey is probably about the best wound dressing there is. Cuts, burns, you name it. Always keep some around.9 points

-

9 points

-

9 points

-

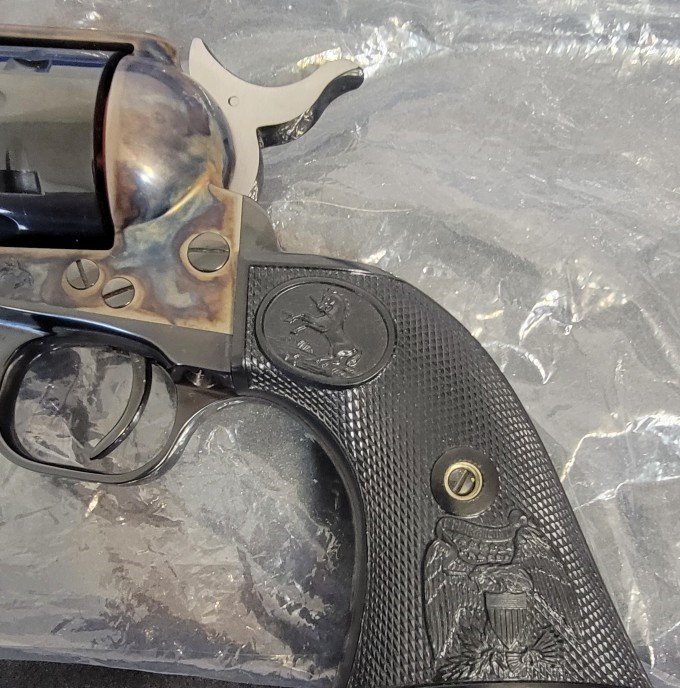

As title states CONSECUTIVE SAA's in 45 !! 2008 production with removable cylinder bushings, much like the 2nd gen guns. 4.75" gunfighter length barrels!! Magnificent case colors as pics show. These were purchased NEW and kept salted away. Original owner knew their value and kept them as an investment. Handled very little as evidenced in pics. Not too many consecutive sets to be found these days. Don't miss out. Come in blue custom shop box with all paperwork and white over sleeves. ALL sales are ffl to ffl. Price is for the pair.......$5200.8 points

-

A couple of weeks ago I started a thread about my first Aldi visit. A few things kind of soured me on my first visit, the unfriendliness of the checkout clerk, the haphazard stocking of a lot of the items…etc. I visited a different Aldi in Escondido and this one was much, much better than the first one. It was much cleaner and organized and looked like the employees really cared. This one is in a larger building that used to be a Sports Authority store in a different part of town, maybe that has something to do with the appearance inside and outside. The checkout clerk was very engaging and courteous. I’ll shop at this one again.8 points

-

OK.. complete tear down and deep cleaning last night.. finished up just now.. Upon tear down.. I was taking the bolt extension and bolt out.. normal.. Tipped the bolt up to remove firing pin.. it didn’t come out.. Tried it a few times to no avail.. finally straightened out a paper clip and poked it out.. an extra piece came out with it.. Where the heck did this come from?? I’ve never seen it before.. that was probably effecting the firing pin travel.. duh upon inspecting the bolt and bolt extension I noticed a piece was missing on the tip of the keeper end of the bolt extension.. (Yep.. Garrison Joe called it) Now I thought that extension was made out of a solid piece of steel.. It’s not..it’s two pieces… one piece of steel tube pressed over another piece of steel Rod.. and then I guess milled to their specs.. (don’t pretend to know how they make them) but that broken off piece.. I think.. was causing the problem.. I had a new spare ‘73 bolt assembly and installed it after finishing all the other deep cleaning.. I also backed the hammer spring straining screw off that 3/4 turn.. back to original.. can always turn it back.. The hammer spring is leaf type and doesn’t looked like it’s been hour glassed to lighten it.. Gotta go shoot it now.. Thanks for your patience and time..👍🏻 Rance8 points

-

8 points

-

8 points

-

8 points

-

8 points

-

8 points

-

As an old gentleman, you can never be overdressed. A mirror, when you’re an old geezer Can leave you feeling distressed You should try not to do it while naked Go get yourself properly dressed And you know what I mean by properly A neatly pressed shirt for a start No backwards ball cap on your noggin No jeans that are falling apart A proper fedora’s a nice touch Or a Stetson if the mood is just right or even a Boater in summertime To ward off the sun’s rays so bright Properly cleaned and pressed trousers A crease like a knife’s a nice touch And a good belt to hold up your pants please Or you’ll look like a gangsta and such Shine your shoes, add a tie if you want to A vest if the weather turns cool But avoid a fur collared raccoon coat You don’t want to look like a fool Now go back and look hard in the mirror In you classy fine hat and new suit Go stroll around town with some pride for a change The young girls might say “Awww. Ain’t he cute!” They say “Clothes make the man”, well not always But they’re handy if it starts to sprinkle And one very important factor is They will certainly hide most your wrinkles8 points

-

To all the posters suggesting that new shooters "just go buy stuff" you are doing them a great injustice. That may be fine for someone with an unlimited budget that can afford to replace everything as soon as they start, but is not practical for most. I teach a monthly "new shooter" clinic at my home club and can let them try different grip frames, calibers, rifles and shotguns BEFORE they buy something they'll want to replace 2 months later. I can also save them money by turning them on to quality equipment that current shooters want to let go of. I can't tell you how often I've had people show up with jacketed hollow point ammo, holsters that are for the wrong size frames, illegal items, firearms that don't suit them or are not allowed, etc. PLEASE suggest potential new members go to any club and they'll probably get at least some basic advise and get to try a few things out before making some bad decisions.8 points

-

8 points

-

I actually did see this on a stall wall. For a good time call, 867-5309 Jenny It was after the song came out though.8 points

-

8 points

-

8 points

-

8 points

-

8 points

-

8 points

-

It's the heat, caused the fractionalizer whompageezer to defrogmify, threw the whole thing out of kilter.8 points

-

Just got back from testing firing both rifles.. the problem child (Pioneer Gunworks) rifle worked great with no jacked out rounds.. and with the hammer screw backed out to original place.. My backup ‘73 was built by Griners out west.. I had him build it with the Pioneer Super short stroke.. It worked perfectly too.. It actually levers easier than the problem child.. I had a fellow cowpoke there that can shoot and cycle the rifles a heck of a lot faster than me… I had him run thru 10 rounds twice in each rifle.. No fail to fires in his 40 rounds and my 40 rounds.. 👍🏻7 points

-

7 points

-

7 points

-

There is a great documentary about the filming of JAWS on Disney + and HULU (no comments please, the grandkids enjoy it when they visit). Quint's history of hating sharks needed an explanation, and a screenwriter suggested the Indianapolis story. Shaw wrote the final version, delivered the first effort drunk, reshot the scene sober after apologizing to Spielberg. Acting genius to deliver his story with a faint smile. Breathtaking!7 points

-

It scared the daylights out of me, and I had never swam in the ocean. As an aside, I will argue that the USS Indianapolis scene is the single best piece of acting ever caught on film. It seemed Shaw stopped acting, and Dreyfuss and Scheider were mesmerized.7 points

-

I got out a package of Innovasian Orange chicken for my supper. It's pretty good for a frozen meal but not used very often. They make a number of other dishes that I use more often. Anyway, I preheated the oven to 400 degrees, opened the package, dumped the chicken into an oven-safe dish, and put the sauce in warm water to thaw. I heard the buzzer go off, went in and put the dish in the microwave, and set the timer for 22 minutes, pushed the button and went back to the book I was reading in the living room. . . . . . . . . . Did you catch that? Fifteen minutes later I went in to check the meal and found the kitchen full of smoke......and a dish full of chicken nuggets cooked to the consistency of paving stones. Why the smoke alarm didn't go off is a mystery for later. I turned the oven off and made myself a grilled cheese sandwich, opened a bottle of sarsaparilla, and read some more. I'm up and will clean up the mess later. Just remember, POBODY'S NERFECT!7 points

-

7 points

-

7 points

-

7 points

-

7 points

-

Although .22s got started in this area as a way to avoid hunting for rifle brass in the snow, we have more than one club in the area that allow .22s any time you want to shoot them. We just figure out what to call the category when needed, “Senior Buckaroo” being one example. We have even included “mild bunch” in our Wild Bunch matches allowing .22 1911s and rifles. I do not think it has brought in any new shooters though.7 points

-

7 points

.thumb.jpeg.cc57f04a9d0b2cb5f538a007d65ffd52.jpeg)

.thumb.jpeg.9b2f1c157d9935c306e7183749d5d421.jpeg)

.thumb.jpeg.002438c7878c036d1156c8292f398f05.jpeg)

.thumb.jpeg.d21a0ca115bb1c5da1ddfa8b4b070fc4.jpeg)

.jpg.e3f020672b8f9e72668d25798f81b679.jpg)