-

Posts

5,329 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Marauder SASS #13056

-

Handgun Training In Georgia???

Marauder SASS #13056 replied to Rancho Roy's topic in SASS Wire Saloon

There is a shooting range in Newnan, SW side of Etlanta that will teach them. Where do they live? -

So, I want a custom fitted hat, in Arizona

Marauder SASS #13056 replied to Dapper Dave's topic in SASS Wire

A good hatter has that strange looking hat fitting device - looks like it came from a torture chamber. Then the hat can be made just for your head. Most often times, a good hatter can make a "proper" sized hat and stretch/mold it to fit our strange heads - some heads are rounder, some oblong, long-oblong, etc. -

Stoeger Coachgun Opens On Its Own After First Shot

Marauder SASS #13056 replied to johnmuir2013's topic in SASS Wire

Sometimes they are not great when new, but generally because the latch does not go in far enough, there is not enough surface area to hold - thus it wears. When you extend the lock, it significantly increases the life of the lock up. If you weld it up as johmeir is doing, it is MUCH harder and will out last the rest of the gun. -

Stoeger Coachgun Opens On Its Own After First Shot

Marauder SASS #13056 replied to johnmuir2013's topic in SASS Wire

(Larsen, that's for the great explanation and photos.) johnmuir The bottom photo is great. It shows that your system is doing pretty well for the proper length, better than many. The problem is the wear - look at the downward curve of the locking surface. It needs to be straight. So you are in luck and can have a great, strong gun once more. So you need to find a good welder. Have them weld up that curve. Then you can file it down to a good level surface and the locking will be good and will not require a strong spring at all. -

Sorry to hear that, Cas but we understand. Stay busy and keep your mind working!

-

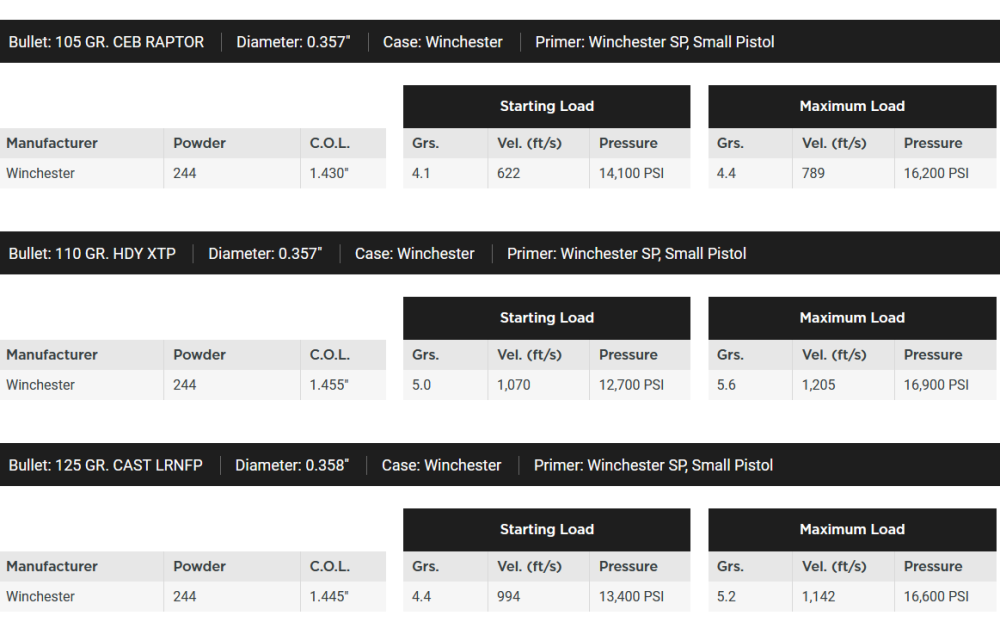

Anyone using Winclean 244 powder for CAS?

Marauder SASS #13056 replied to Jackson Haller's topic in SASS Wire

-

Never let that stop you. The first year I shot SASS, I was also sorta intimidated so I missed a wonderful time at Round-Up. Remember it is abut fun and friendships as well competition. As you shoot more you will generally improve. Your primary competition is not so much other shooters as it is yourself - getting smoother and maintaining accuracy.

-

Some thing to consider. At my stage of life, a lifetime warranty doesn't mean as much to me. Plus my home windows have a lifetime warranty, but the company went under while with windows were in great shape.

-

Texas Maverick, the obvious solution is to buy a 1050. You know you wanted one anyway, right?

-

Question - when can you touch SG loads?

Marauder SASS #13056 replied to Ashley D Austin's topic in SASS Wire

You should Never touch shotgun shells. They are very dangerous and should only be handled by professionals... Such as the not-so Secret Service??- 72 replies

-

- 16

-

-

-

I find it almost funny that security is so strongly emphasized but we are generally not allowed the more secure methods ourselves - one of which is a VPN. Many websites want to look into my computer for their protection, thus decreasing my protection. So 2 factor is sorta helpful but it reminds me of "duck and cover" during the 1950's to some extent. What about those without a cell phone! (I know, I can usually use my email.)

-

A SAD NOTE: BLACK GOLD SHOOTOUT!!!

Marauder SASS #13056 replied to Blackwater 53393's topic in SASS Wire

So sorry to hear of a great loss. -

A SAD NOTE: BLACK GOLD SHOOTOUT!!!

Marauder SASS #13056 replied to Blackwater 53393's topic in SASS Wire

I found it at the bottom of the page. Thanks! -

A SAD NOTE: BLACK GOLD SHOOTOUT!!!

Marauder SASS #13056 replied to Blackwater 53393's topic in SASS Wire

Not here: https://ponderosa-pines.com/match-results Could you provide a link? -

A SAD NOTE: BLACK GOLD SHOOTOUT!!!

Marauder SASS #13056 replied to Blackwater 53393's topic in SASS Wire

Have the scores been posted? -

Find a friend with a laser printer. It is so much cheaper per page than ink-jet.

-

My experience matches Concho Billy's. But I have to send to an FFL and pay a reasonable fee to them. So often times, I can get almost the same deal from a local FFL, thus easier and help local folks.

-

Do 'P's increase with hot weather?

Marauder SASS #13056 replied to Widder, SASS #59054's topic in SASS Wire

A general rule is as match difficulty increases, you will first see an increase in misses, then an increase in Procedural s. That is true for the weather conditions as well as the match design. -

Is it possible to shoot Duelist with only one revolver?

Marauder SASS #13056 replied to Deadeye Joe's topic in SASS Wire

Funny how times changed. When I started several stages called for only some of the guns we now use. Sometimes only 1 pistol. Sometimes no shotgun, etc. I still have a bunch of old stage instructions that way. And it was not uncommon to have a shooter come with only 1 revolver. It was his or her choice to either reload on the clock or take the misses. We didn't have the Gunfighter category back then. But now, you might be able to shoot gunfighter with 1 pistol - just taking a miss for every other target . Don't see that it would matter much, but you could shoot in two handed category or duelist if you wish. -

Ed Seiker, Texas Ranger has passed

Marauder SASS #13056 replied to Possum Skinner, SASS#60697's topic in SASS Wire

So sorry to hear! RIP Praying for the family. -

New Guns from Taurus/Rossi/Heritage

Marauder SASS #13056 replied to Chicken George*'s topic in SASS Wire

That is definitely a change and is encouraging! When I spoke on the phone with them on two occasions, they refused to send parts to any gunsmith. I clarified if they would send to ANY gunsmith and at that time their police did not allow it. Everything had to be done by them or the warranty was voided. I certainly hope they come around! -

New Guns from Taurus/Rossi/Heritage

Marauder SASS #13056 replied to Chicken George*'s topic in SASS Wire

Yup, Josh Randall is so disappointed... https://www.imdb.com/title/tt0051327/mediaviewer/rm3 827668225/ -

New Guns from Taurus/Rossi/Heritage

Marauder SASS #13056 replied to Chicken George*'s topic in SASS Wire

The GX4 series. I know it is for the regular and XL and suppose it is true for the GX4 Carry as well. Nice guns, so I wish they would support them better. -

New Guns from Taurus/Rossi/Heritage

Marauder SASS #13056 replied to Chicken George*'s topic in SASS Wire

I have one of their modern semi pistols and love it - But they will NOT sell most parts to ANYONE. I called them and asked several times about commonly replaced parts such as a spring or extractor. No explanation other than "It's our policy." If the parts wear, send them in (at your expense) and they will evaluate whether they will fix it as warranty or at your expense. So, once the gun wears, it is a "thro-away."