-

Posts

5,581 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Abilene, SASS # 27489

-

Uberti 1886 Sporting Rifle in 45-70

Abilene, SASS # 27489 replied to C. W. Knight # 47289L's topic in SASS Wire Classifieds

I didn't do anything on the phone, just clicked on the topic like normal. I don't know if these pics show up on my laptop now because it just ^@#% died. -

1866 rifle wonderment and my fix…I hope.

Abilene, SASS # 27489 replied to Matthew Duncan's topic in SASS Wire

Did your calibrated "thumb gauge" feel any difference in effort to thumb cock the hammer with the 2 different springs? -

Shotgun boogies "66-style " loading gate for the '73 makes it easier to load also.

-

Uberti 1886 Sporting Rifle in 45-70

Abilene, SASS # 27489 replied to C. W. Knight # 47289L's topic in SASS Wire Classifieds

They show up good on my android phone. -

Uberti 1886 Sporting Rifle in 45-70.

Abilene, SASS # 27489 replied to C. W. Knight # 47289L's topic in SASS Wire Classifieds

Dang, technology sure can suck. Bring back the telegraph! -

@Colorado Coffinmaker has one, he can tell you more. I think he said it is identical to the Pedersoli and probably made by them.

-

Uberti 1886 Sporting Rifle in 45-70.

Abilene, SASS # 27489 replied to C. W. Knight # 47289L's topic in SASS Wire Classifieds

On my Windows 10 laptop, I right-click the link, then select Open Link in New Tab. That does not open another tab, but downloads the file. I go to my downloads folder and from there both the Photo viewer and Paint will open the image. -

The Holy Black is a term for Black Powder. O.O. is being sort of an elitist plenty of time for BP later (it's worth the wait). My suggestion: to start with, order loaded .38's from Bullets by Scarlet. You have to pay shipping, but the cost per round will likely be less because store ammo is expensive, plus it will be loaded for CAS. Save the brass. If you are using a side by side shotgun, in general avoid ribbed hulls and hulls with a base that is silver. Those tend to stick in the chambers and don't shuck well. If you can find the Winchester AA LNLR by all means get them. They say Low Recoil Low Noise on the box but also look for 980fps. If you can't find those, AA's that are 1 oz at 1180 fps are about the next lightest load. 1 1/8 oz at 1145fps kick harder. You can get those loads in the Winchester white box but those will have the silver base. If you are shooting a '97 then it will eject most anything. Regarding your dies question, almost any dies will make decent CAS .38's. I've used nothing but inexpensive Lee for years along with their Factory Crimp Die, and no complaints. Welcome aboard and have fun!

-

Your price range will probably eliminate Rugers, these days. That would be about the price for used Italian guns. The Ubertis and Piettas can be slicked up easily. If the timing is good, they really only need a spring kit. Some Piettas have come from the factory with lighter springs already. With some exceptions, most Cattleman made the last half dozen years will have their telescoping firing pin safety which usually is okay but some people have had issues with that. People will say that Rugers are the toughest, but a properly set up Colt or Clone can be very reliable. For sure, go to a match and ask to handle some guns. As mentioned above, some will just feel better in your hands than others.

-

Rossi R92 firing rounds not fully seated

Abilene, SASS # 27489 replied to Mad Major's topic in SASS Wire

I'm not sure why I didn't notice this thread before. Regarding the issue of it being hard to chamber a round that last little bit, that is pretty normal on '92's. It is the ejector on the face of the bolt being pushed into the bolt by the base of the cartridge as you chamber it. That is why you don't feel it when cycling the action with no ammo, because the ejector doesn't push into the bolt face. The ejector spring inside the bolt is stout, and action jobs and spring kits involve lightening or replacing that spring so it takes less effort to close the action while chambering a cartridge. -

Crinkled Brass After Reloading on my Dillion 650

Abilene, SASS # 27489 replied to Texas Maverick's topic in SASS Wire

Yeah, I think you need a little more crimp now, too. But glad you got it sorted out. As for those wrinkled rounds, just push them real, real hard into the case checker - that will iron them out and then you can shoot them next month at State. -

Primers not going BOOM turns out to be operator error.

Abilene, SASS # 27489 replied to Cholla's topic in SASS Wire

Heehee, never had any of those problems vibrating in corncob and walnut. My lead levels are okay. It ain't broke so I ain't fixing it. Sorry, couldn't help it. -

Crinkled Brass After Reloading on my Dillion 650

Abilene, SASS # 27489 replied to Texas Maverick's topic in SASS Wire

Hey Mav, since this just started, can you remember adjusting anything recently? I would do the cleaning you mentioned, make sure everything is tight, and then just start loading slowly. It seems to happen often enough that you should be able to spot where it is happening. -

I doubt it. Think about it, the press never removes the dimple from any primer that gets punched out completely, so why would it remove the dimple from one that was only partially punched out? And I don't know about the 650, but on my 550 a primer that is only pushed partially out (or a new one partially seated) will not allow the shell plate to turn.

-

No, sir! Last shot has to be on P3.

-

I would say no, because like you said, a miss can't cause a P. Around here when a stage is written like that, it will often have added "no double taps" or "no triple taps"

-

Bear in mind also that SASS and a lot of local WB matches are now using 7 rounds in the magazine. Which makes a revolver a little less practical, unless you just like reloading.

-

In the back?

-

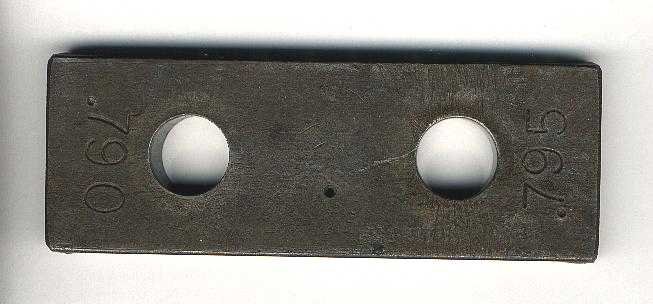

Looks like a 4th number on top tang. 7155? 7153? They look to be hand stamped as the spacing and height of the letters varies some. And the bottom looks more like 716 to me.

-

Enjoyed meeting you and the Misses, Red. Now you got me thinking...I just checked, and it should be possible to fit SEVEN buckles on a hatband!!

-

And the Uberti 73 parts winner is?

Abilene, SASS # 27489 replied to Badlands Bob #61228's topic in SASS Wire

I guess I don't shoot enough (I certainly don't practice). My three most-used toggle guns have between 7K and 10K rounds of BP and smokeless through each, and have never had a failure to extract. BUT - - I did buy the kit from Scarlett and it's in my cleaning gear, because I know the time will come. I suppose if I just shot one rifle it would happen sooner. -

Or maybe chamber a single round through the loading port, then fill the tube with regular 250 grainers. You'll have to remember to just cock the hammer for that first shot, though.

-

Jim, thank you for giving me the impetus to finally look into a similar problem that began when I installed a Shotgun Boogie " '66-style " gate in my '73. I put up with it because it was only the last round that was a pain (and I am lazy). It looked like this was going to be the same thing, with the bottom of the gate hitting the spring or lifter arm. Turns out the outer edge of the stop tab was hitting a humongous machining burr in the frame opening to the left. All I have at this location is a fine-toothed file so it took a while and it didn't take much off that burr, but enough. Did a little cleaning while I was in there, since the last time it was apart was when I put the loading gate in. It was surprising clean though, but then I'm using one of your V-V loads.