-

Posts

10,932 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Everything posted by Larsen E. Pettifogger, SASS #32933

-

Wallace & Ladmo were favorites when I was going to ASU (Arizona State University) in the 60s. Their humor while amuzing for kids was really adult oriented. I worked at Legend City for pocket money while at ASU. They even had a restaurant which if I remember was on Bethany Home Road. Those Ladmo burgers were pretty good.

-

Start lines

Larsen E. Pettifogger, SASS #32933 replied to Possum Skinner, SASS#60697's topic in SASS Wire

I remember one year at EOT where Bob Boze Bell recorded the "scenes" for each stage on casettes and they played them on a boom box at the beginning of each stage. Damn near caused a riot. No one wanted to wait arount for ten minutes while Bob regaled everyone with tales of the old west. I think it lasted maybe two stages and they junked the boom boxes. 95% of matches don't have them because 95% of shooters don't give a crap about them. -

Rossi 92 aftermarket spring sets, availability

Larsen E. Pettifogger, SASS #32933 replied to Jhon's topic in SASS Wire

Shotgun Boogie makes a complete tune-up kit. https://sbgwllc.com/shop/rossi-mod-1892-tuning-kit/ I saw Palo Verde last night at our Trap shoot. The problem is that most American dealers will not/can not ship parts out of the country. -

Start lines

Larsen E. Pettifogger, SASS #32933 replied to Possum Skinner, SASS#60697's topic in SASS Wire

Philly Slim would have. -

Start lines

Larsen E. Pettifogger, SASS #32933 replied to Possum Skinner, SASS#60697's topic in SASS Wire

Shooter Ready? . . . Nod or yes from shooter . . . Standby . . . . . Beep. Note, It is NOT Standbleep! -

No big deal. You can probably bent it cold with the lever still in the gun. The metal is not that hard. Just put a cresent wrench on the tab and pull it over to the right. If you are ultra cautious you can remove the lever from the gun and heat it. If you do it cold and it breaks Numrich sells them for $12.00. (Look under Boito rather than Stoeger.) Are you left handed? Most right handers would have not problem with that bend.

-

RCBS Cowboy Dies Discontinued

Larsen E. Pettifogger, SASS #32933 replied to Cotton Eye Joe's topic in SASS Wire

You guys are missing the whole point. The RCBS COWBOY dies were pretty and said COWBOY on them. The regular dies were ugly and did NOT say Cowboy on them. Thus the Cowboy dies were demonstrably superior.- 22 replies

-

- 18

-

-

-

-

BULLET CASTING QUESTION

Larsen E. Pettifogger, SASS #32933 replied to No Horse Hair, SASS #77464's topic in SASS Wire

These guys are the experts on bullet casting. You should try posting over there. https://castboolits.gunloads.com/showthread.php?256528-Wrinkled-bullets-after-an-hour-trying -

Ruger Revolver help/info

Larsen E. Pettifogger, SASS #32933 replied to Doc Moses's topic in SASS Wire

8-36 #29 pilot drill and you must use a bottoming tap. Look at the hole in the factory barrel very carefully and take note of it's shape and depth. Not much material there. You might want to consider making the hole with an end mill and custom grinding the bottoming tap so it will go to the bottom of the hole. -

Opinions on Hammer Stops?

Larsen E. Pettifogger, SASS #32933 replied to Bladesmith, SASS 113085's topic in SASS Wire

What stops the hammer from traveling backwards on a stock gun is the pawl pushing on the cylinder racthet. On many guns if you twist the cylinder counterclockwise with your left hand and put rearward pressure on the cocked hammer with your right you can feel the pawl pushing on the ratchet. If you are really aggressively slamming the hammer back this can cause wear to the pawl or ratchet. There is usually no performance gain from adding the overtravel stop. What you gain is potentially less wear. -

SASS Rugers VS Taylor's SASS PRO Short Stroke

Larsen E. Pettifogger, SASS #32933 replied to Squib Kidd's topic in SASS Wire

???? The Arizona Ranger is not a short stroke. -

SASS Rugers VS Taylor's SASS PRO Short Stroke

Larsen E. Pettifogger, SASS #32933 replied to Squib Kidd's topic in SASS Wire

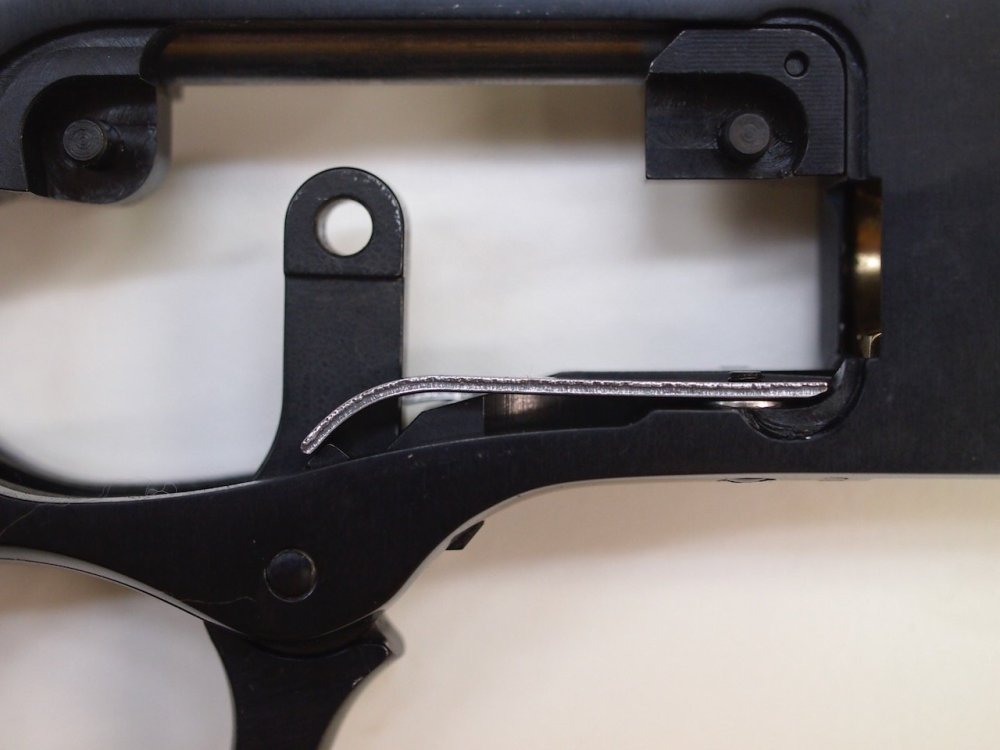

Just as an FYI "SASS Pro" is a Uberti brand nomenclature. Taylor's version of the SASS PRO is called the Running Iron. I bought a pair just to see what makes them tick and photographed a lot of the work for a possible future Chronicle how-to article. You question does not have an easy answer. None of my guns are stock. Straight out of the box the SASS Rugers and Uberti short strokes both leave something to be desired. Straight stock I would give the edge to Ruger. Without getting into a lot of detail the Uberti's were quite interesting and I found seveal areas where they had excess friction and this impeded getting a smooth light action. I noticed on the Taylor website even for their Taylor Tuned Running Irons they noted "the spring pressure is left at factory settings for optimal performance." This was obviously to overcome internal friction and to ensure reliable ignition. Well the spring pressure was not comfortable for me so I started tuning the guns with an eye towards reducing the mainspring and bolt/trigger spring pressure. I won't go into detail about how the retractable firing pin works. Suffice it to say when you pull the trigger you are not pushing the firing pin rod UP and forcing the firing pin forward. The rod gets pushed when the hammer falls DOWN into the extension on the back of the trigger. That happens right at the moment of ignition and softens the hammer fall. So the first thing was to machine some rods to replace the factory rods and hold the firing pins forward all the time. The trigger is interesting as it has two "sears". The normal one (green arrow) on top which engages the half-cock to load and unload the gun and the purple arrow which is the short stroke sear on the back of the trigger. The hammer "full cock" notch sits on the second sear. Because both sears are present it is possible under certain circumstances to cock the hammer to its normal full cock position. So I added a hammer stop to limit hammer travel to allow just enough travel to engage the short stroke sear. The short stroke bolt (bottom) is significantly different than a standard bolt (top). It took some very judicious fitting to correct the timing and stop the cylinder from over rotating. I reduced the spring tension significantly and the guns are actually quite a pleasure to shoot. So my tuned Running Irons vs stock Ruger I'll take the Running Irons. Short stroked Rugers (of which I have several) vs. Uberti short stroke is more a matter of what feels best in your hand. They do feel different. It is odd but when I am cocking the Rugers it feels like I am pulling the hammers to the rear. When cocking the Ubertis it feels more like you are pressing them downwards. I have over 1,000 rounds through the Ubertis and so far they are working surprisingly well. A word about the retractible firing pins. Like many things on the wire a lot of comments are from people that do not have them. The design is actually quite clever and pretty fool proof. HOWEVER, they are not idiot proof. There are people that cannot shoot Glocks because they limp wrist them. There are some that cannot shoot certain types of double barrel shotguns because they are slapping the trigger(s) or not holding the gun tight against their shoulders and getting doubling. On the Ubertis you have to pull the trigger all the way to the rear. If you tap it or slap it you may well get light strikes. To be sure the old style solid firing pins are more idiot proof. Unless there is an actual mechanical malfunction the retractable pins are not as crappy as a lot of people make them out to be. -

It depends on what you want to do with it. If you only wanted to pop off a few shots at 25 yards you could probably get it do that. But I notice that you want to be able to shoot at least 200 yards. I had an officer's model and that rear sight is totally useless. From your photo it looks like it is the one that you loosen the eye piece and the eye piece will move up/down and left/right. It is completely non-repeatable and if you get it zeroed at any particular distance it is a matter of pure luck. The sight is also set directly into the wood stock with just a couple of wood screws. Not a very secure system expecially since the 45-70 can have quite a bit of recoil. And, as previously noted, the sight is "floppy" and is going to fold with almost every shot. If you want to do any serious shooting and actually reliably hit targets at 200 yards your best bet is to junk the sight is and buy one with vernier or click adjustments. What a lot of people do is make a steel base that is three or four inches long and about 1/4" to 5/16" thick and inlet/glass bed that into the stock along with some decent screws. The new base is drilled and tapped for metal screws and the new sight screwed to that.

-

President Garfield death

Larsen E. Pettifogger, SASS #32933 replied to Rye Miles #13621's topic in SASS Wire Saloon

https://longstreet.typepad.com/thesciencebookstore/2011/05/precursor-to-telephoning-the-dead-the-telephone-x-ray.html#:~:text=--basically%2C the device was,of a proximate metallic object. -

In need of MEC bushing info

Larsen E. Pettifogger, SASS #32933 replied to Sgt. Hochbauer, SASS #64409's topic in SASS Wire

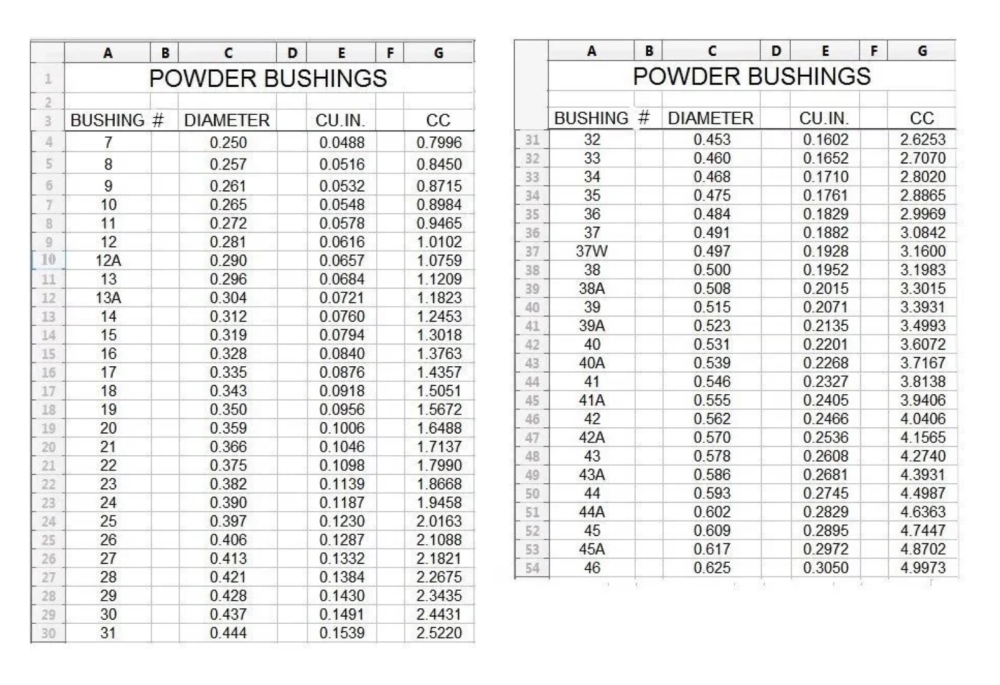

Not to be argumenative and not directing anything at you, you did not say what the bushing is supposed to drop. You just said here is a load you got from Scarlett. If it is supposed to drop the charge the OP was asking about a clear answer would have been "a #18 bushing should drop X grains". We all need to be careful when providing loading data. SASS use to not allow loading data because of typos and people providing untested data. There use to be a member that frequented the wire with the alias of Birdshot that worked for Hodgden. Many times he had to post warnings that suggested data was unsafe. His testing is why SASS does not allow "tapering" shotshells. "Shotgun shells shall not be sized down (necked) by the use of any die not manufactured for the specific gauge." Several years ago several shooters would run their 12 gauge shells into a 20 gauge sizer and squash the end of the 12 gauge down. This was supposed to facilitate loading double barrel shotguns. Birdshot tested the practice and found this raised pressures well above the max allowed for a 12 guage shotgun. One thing that is a PITA is that MEC numbers do not tell you the hole size. Hornady, RCBS, Spolar etc use the actual bushing ID as the bushing number. I.e., a #456 Hornady bushing is .456 ID. MEC conversion tables are hard to find but here is a chart showing MEC ID sizes just as an FYI for the wire. -

There are few aftermarket parts because there are few Winchester Miroku 73s in circulation. Not worth tooling up parts if you are only going to sell a handful. The Miroku is designed differently than an original or the Uberti 73. What are you trying to accomplish? I have found that due to the lack of aftermarket parts and the scarcity of factory replacement parts a few little cautious tweaks to the Miroku make a big difference. For example, the lifter and lever springs on the Miroku (top) are basically flat and quite flexible. When installed they have very little bend in them. The Uberti and Winchester and quite arched and very stiff and as you tighten them they straighten out quite a lot. What I have found that works quite well is to simply put a washer between the spring and the seat. This makes a noticeable difference since as previously noted there is very little bend in the springs when they are installed. The mainspring has the same characteristics. It is relatively flat and does not flex near as much as the Uberti or Winchester. EXTREME caution needs to be excercised if you are going to attempt to modify the factory spring unless you have a replacement in hand. It can go from plenty of pressure to almost none with just a few thousands of an inch of material removed from it.

-

In need of MEC bushing info

Larsen E. Pettifogger, SASS #32933 replied to Sgt. Hochbauer, SASS #64409's topic in SASS Wire

Not really useful information. There is no wad given and more importantly there is no charge weight. MEC bushing charge weights are STARTING points. The chances that the charge will weigh what the chart says is virtually zero. Powder density varies between batches. Charge weight can vary immensely depending on the loader's loading technique. Charge weights vary between, for example, a MEC 600 single stage press and a MEC 9000 progressive press. Without a charge weight loading data is not data. It is useless. -

jan 1961 MAD Magazine #60

Larsen E. Pettifogger, SASS #32933 replied to Father Kit Cool Gun Garth's topic in SASS Wire Saloon

When I was in the Army I was in a plain clothes MI unit. MOS 9666. Our unit, the 701st MID (Military Intelligence Detachment), had the Spy as our logo/mascot. When I left the army in 1971 the unit was closing down so I took the mascot with me. Somewhere over the years during a move it turned up missing. All I have left is one of the key chains we had made up. -

Paying cash at the store

Larsen E. Pettifogger, SASS #32933 replied to Rye Miles #13621's topic in SASS Wire Saloon

Your interpretation is simply wrong and not how the Fed or the courts intrepret the language. Several states have passed or are considering legislation to require retailers to take cash. A retailer is not a creditor. For example here is the provision being considered by Arizona. https://www.azleg.gov/press/house/56LEG/1R/230223CHAPLIKHB2555.pdf -

Bad happening at loading table.

Larsen E. Pettifogger, SASS #32933 replied to Hoss's topic in SASS Wire

-

Paying cash at the store

Larsen E. Pettifogger, SASS #32933 replied to Rye Miles #13621's topic in SASS Wire Saloon

WRONG! This is the section right after the language I quoted above. Section 31 U.S.C. 5103, entitled "Legal tender," states: "United States coins and currency [including Federal Reserve notes and circulating notes of Federal Reserve Banks and national banks] are legal tender for all debts, public charges, taxes, and dues." This statute means that all U.S. money as identified above is a valid and legal offer of payment for debts when tendered to a creditor. -

Paying cash at the store

Larsen E. Pettifogger, SASS #32933 replied to Rye Miles #13621's topic in SASS Wire Saloon

More and more store will not even accept cash. I got into a "discussion" with one retailer and then checked when I got home. This is off the Federal Reserve website. Apparently the policy changed in 2020. Stores do not have to accept cash. Is it legal for a business in the United States to refuse cash as a form of payment? There is no federal statute mandating that a private business, a person, or an organization must accept currency or coins as payment for goods or services. Private businesses are free to develop their own policies on whether to accept cash unless there is a state law that says otherwise.

.thumb.jpeg.c142b7549a685b30f0ca546dc5b8606f.jpeg)

.thumb.jpeg.50bd4ca7a14ddce7f2e10ec1ede13e0d.jpeg)

.thumb.jpeg.c83625117c10542c0fb12eb092ad1c4d.jpeg)