-

Posts

11,142 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Everything posted by Larsen E. Pettifogger, SASS #32933

-

-

It has the old Vaquero hammer.

-

Long Hunter Operation

Larsen E. Pettifogger, SASS #32933 replied to Long Hunter SASS #20389L's topic in SASS Wire

Good luck Jim. Should not be near as windy as Amarillo. -

The "trigger safety" has nothing to do with keeping the firing pin retracted. It's purpose is to keep the hammer cocked until the lever is closed. Most OBD's are shooter induced by slapping the lever trying to force in a round. Edit. The firing pin extension is heavy. When you slap the lever and the bolt comes to an abrupt halt the extension keeps traveling forward by inertia.

- 17 replies

-

- 11

-

-

-

A while back someone asked if Glock ever made plastic magazines. For whatever reason the thread got locked but I found these in my junk box and thought I would answer. I bought one of the first Glocks imported into the US in 1986. At that time the magazines were plastic except for the feed lips which appear to be stainless steel. These magazines were junk. If you loaded them up to capacity they would not drop free of the gun. The springs were made from some material that would take a set after only a few loadings so you could only fire the top 9 or 10 rounds. The rest stuck down in the magazine. The magazine bodies themselves were made of some material that was not terribly durable. Here is a photo of those original two magazines. The plastic bodies on both have split. Glock corrected these problems and these old magazines are now relegated to history.

-

Anyone still making earthwalker boots?

Larsen E. Pettifogger, SASS #32933 replied to WiggleyDY's topic in SASS Wire

-

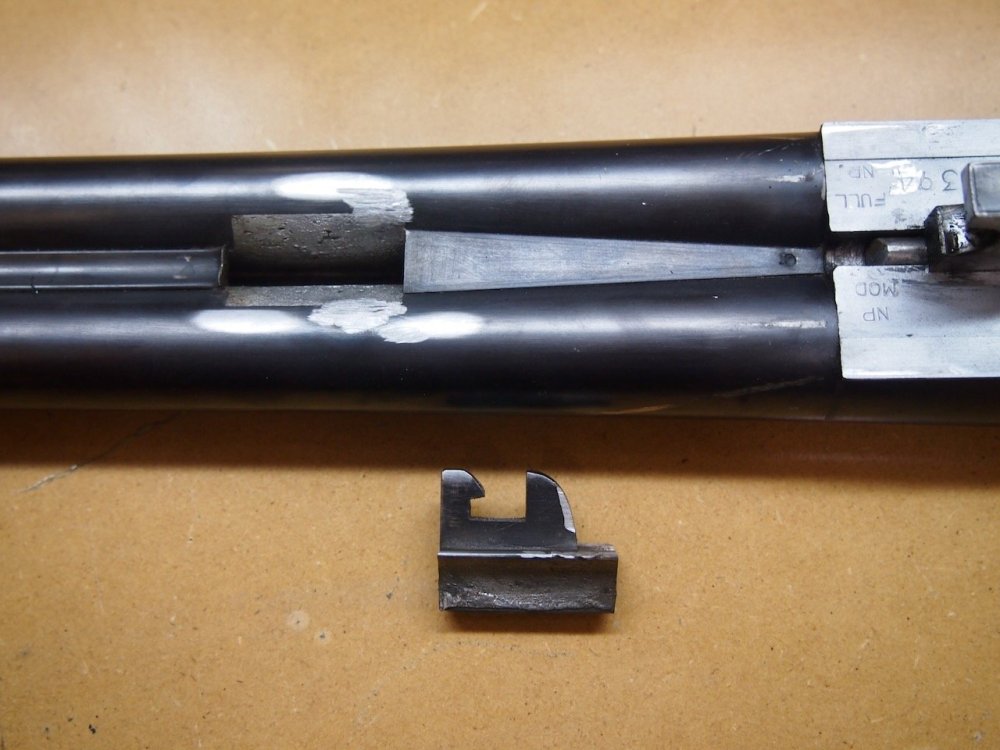

I am no longer familiar with who does SKB work east of the Mississippi. Go to the FAQs and look at the Cowboy Gunsmiths thread. Solicit some suggestions on who is ACTUALLY doing SKB work and check the list. You should only need to send the barrels and no FFL is needed. It can go USPS, UPS, FedEx as it is just a part and not a gun. As you have found out for a one shot repair the cost of materials is about what a lot of smiths would charge for the repair.

-

I do not post much any more but want to make sure you do not ruin your gun. Do not use silver solder as the heat required would melt the solder holding the barrels together and probably ruin your barrels. Welding is also not a good repair method. The barrels are soft soldered. For the repair use soft solder or at most use low temp Hi-Force 44 from Brownells. This is a fairly common problem with SKBs and Johnny Meadows, Boomstick or any of several other SASS smiths that work on SKBs should be able to fix it. In all candor Briley might not even do the job once they see SASS hacked barrels and funneled chambers. Plus the cost would be high. Here is the typical set-up. First photo is the separated lug. After the part is cleaned and retinned and the joint fluxed the lug is placed in the barrel. An iron rod is placed on either side of the lug and the barrels wrapped with soft iron wire. These act as heat sinks. Apply heat to the area and the solder will melt and flow. The repair usually does not require reblue as the temps are relatively low.

-

Derringer Recommendations

Larsen E. Pettifogger, SASS #32933 replied to Sheriff Dill's topic in SASS Wire

Was reading this thread and went over to the local Cabellas today. The gun I wanted was sold but they had this little fella. I have some of that modern made Brazilian .41 ammo so I figured what the hell and bought it. When I got home and checked it out more closely it was sort of a good news bad news situation. The barrel address was unusual as it was stamped into the side ribs rather than the top rib like most other Remingtons I have looked at and owned. Upon further inspection it dawned on me that it does not have an extractor on the left side. Turns out it is a very early 1st Model. That may be good news. However this means this one was made in the late 1860s of low quality steel/high quality iron. The Brazilian modern made smokeless ammo has more pressure than the old BP rounds so not safe to shoot in this early model. It is in better shape than the photos tend to show and was a hell of a deal for $190.00 plus tax. Everything works and the top hinge (a weak point in the originals) shows no sigh of cracking.- 57 replies

-

- 10

-

-

-

Coated Projectiles and Forcing Cones

Larsen E. Pettifogger, SASS #32933 replied to ekiton's topic in SASS Wire

With a "Kirst Konversion 1851 signature series Colt Navy" the issue is not the forcing cone. 51 Navy bore diameter is .375". .38 Special and modern .38 Long Colt use .357/.358 bullets. You do not want hard .357 bullets rattling down a .375 bore. Most people use soft lead hollow base wadcutters that expand to fill the bore. There are also a few bullet makers that offer other bullet style hollow base .38s. Here are a couple of examples. https://www.precisiondelta.com/products/38-cal-148gr-hbwc-ml/ https://www.bearcreeksupplybullets.com/bulletselection https://www.hornady.com/bullets/handgun/38-cal-358-148-gr-hbwc#!/ -

I would go to YouTube and watch the 17 videos produced by Jim Finch AKA Longhunter. They average about ten minutes each. Watch them and observe the gear he uses and suggests.

- 162 replies

-

- 14

-

-

My browsing session is 30 seconds during commercials many times a day. Right now once logged in I stay logged in. My question was is this going to change? I have numerous sites I visit. The only ones that have two factor authentication are generally those having to do with money. Banks, IRA, retirement accounts, etc. I have never run into an enthusisst or hobby site with 2FA. How valuable my time is is no one's business but my own.

.thumb.jpeg.d41eec3d4b49a6620d6ab0af4d98c52a.jpeg)

.thumb.jpeg.a8788b90d62852a8dbaefcbf8c1461d3.jpeg)