-

Posts

3,259 -

Joined

-

Last visited

Tequila Shooter's Achievements

SASS Wire Vet (1/1)

3.4k

Reputation

-

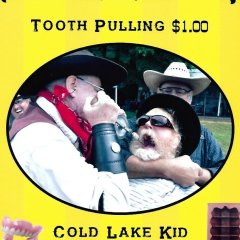

I have not heard back. If you want to send payment via bank check to Robert Glenn

1831 Nadine Rd Apt. 106

Wesley Chapel Fl 33544

It will be yours...BTW it also have sliXshot nipples installed

-

CLK , did you get my PM?

-

Howdy Pard

Got your money! Will ship brass Tuesday if the PO isn’t open tomorrow! Thanks!