-

Posts

322 -

Joined

-

Last visited

About Will Burn Powder

- Birthday 11/08/1960

Previous Fields

-

SASS #

110949

-

SASS Affiliated Club

Elstonville Hombres & The Welsh Mountain Regulators & Blue Mountain Rangers

Profile Information

-

Gender

Male

-

Location

Lancaster PA

-

Interests

Shootin huntin fishin all of the great outdoors!

.............................................................................................................

"Clean Stages and Fast Times to You"

Recent Profile Visitors

1,485 profile views

Will Burn Powder's Achievements

115

Reputation

-

Will Burn Powder started following SPF 25-20 Brass and Dies , SOLD Modified brass carriers for sale 38/357 , FS Ruger SASS Vaquero Set 357/38 with Eagle Gunfighter grips and 7 others

-

SPF - Entry level gun leather

Will Burn Powder replied to Too Tall Bob's topic in SASS Wire Classifieds

Micheal be best to take your private contact info off that post. -

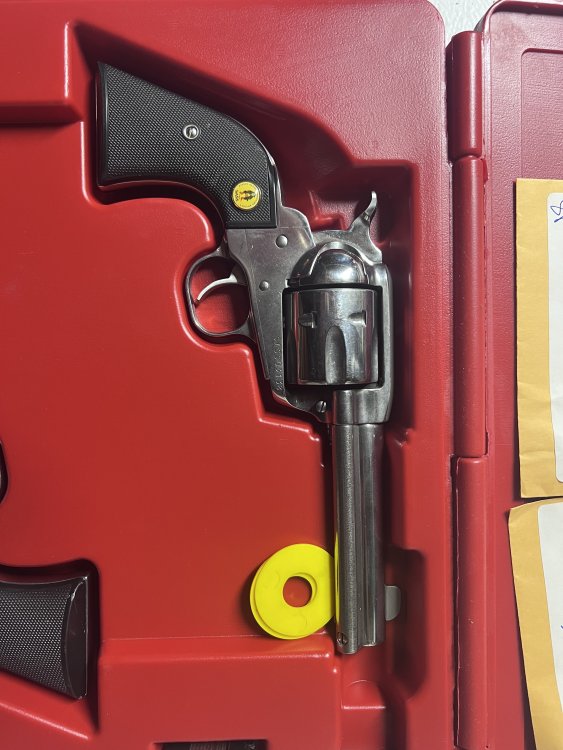

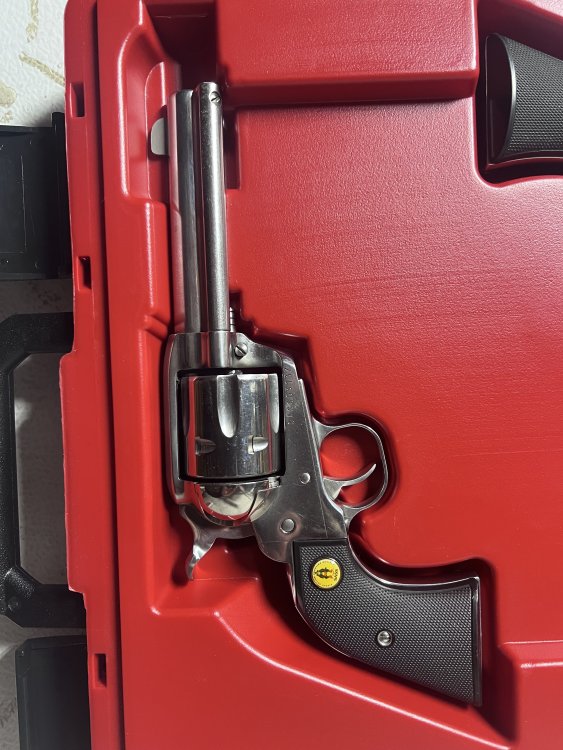

This is a very lightly used (see light turn ring on cylinders) consecutive pair of the older production SASS New Model Vaqueros (newest production models have a lot of QC issues it seems) These are 357 magnum/38 special, they have been slicked and tuned with springs upgraded but no other work done. I will include additional sets of Black Eagle Gunfighter grips to go with these. $2100.00 shipped/insured to your FFL

-

WTB Full Buckhorn rear sight Uberti 1873

Will Burn Powder replied to Dred Bob's topic in SASS Wire Classifieds

Turns out mine was not a full buckhorn sorry. -

WTB Full Buckhorn rear sight Uberti 1873

Will Burn Powder replied to Dred Bob's topic in SASS Wire Classifieds

I might have one I can check when I get home if not Longhunter sells these on his website for about $25.00 -

SPF~Ruger Montado Hammers

Will Burn Powder replied to SGT. ELI 35882 GUNFIGHTER's topic in SASS Wire Classifieds

I’ll take them -

Will Burn Powder changed their profile photo

-

JohnP same guy same scam signed up 45 minutes ago