-

Posts

654 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by "Big Boston"

-

Use chamber checkers AND Lee FCDs?

"Big Boston" replied to Nostrum Damus SASS #110702's topic in SASS Wire

Just a small point, LEE Precision makes a Carbide Factory Crimp die for straight walled cartridges, and a completely differently designed Factory Crimp die for bottle necked cartridges. This thread concerns the Carbide Factory Crimp Die, for cartridges like the 38/357, 45 Colt and 44 Spl/Mag. The 44-40 is bottlenecked and it uses a Factory Crimp die that works differently, it does not perform any case checking. The 44-40 is one of the calibers I reload for, and I randomly check with a case gauge. IMHO having a loaded round pass in a case checking die requires a bit of judicious die and bullet prep/sizing. One of the issues being that the cartridge checking gauge wants a bullet not much bigger than 0.427" in diameter. I use a 0.429" bullet, and for the most part, to pass, it requires a little push, no plunk. Now, to get this thread back on track. If I'm loading for a '73 rifle, I tend to neck size only and use the Carbide FCD die to size the body. Therefore I'll check a bit more often, but I don't check every round. I suppose I just follow the factory practice of random checks, and if there is a failure on a random check, then I check more and determine the issue before continuing. BB -

I did have one, an original Vaquero with transfer bar intact, that would do that. The issue was the firing pin protrusion was not sufficient. The culprit was the transfer bar was too thin. Rugers use lots of formed or cast parts, so dimensions vary. You have firing pin delete, so it's back to mimicking SAA specs. Headspace spec and firing protrusion. If that is correct, put the original spring back in. If that does not work, look for abnormal friction. The heavier the spring, lighter the hammer, the faster the lock time. I have a reduced spring because sometimes my thumb would slip when cocking. The lock time was a bit slower, but my arthritic thumb could do it's job. I shoot duelist, a faster lock time is a good thing, but having your thumb slip is worse. BB

-

I was shooting with a fellow cowboy at the range about a year ago and he had some jacketed 38s and 357 loads that he wanted help blasting off. He loaded up and Pfft, a squib. We quit, and shook our heads. Fast forward to yesterday. I was helping him set up a 3/4 oz load for 20 ga on his LEE LoadAll, and after we were done he hands me 200 plus rounds and the broken pieces from his inertia puller, said I could have it all, that the collets would likely come in handy. I grabbed 9 rounds to try, and they were OK. I called him, and he replied, don't you remember the squib we had. Oh yea, I responded. So I grabbed one more and pfft. So began the pull the bullets. The bullets took a bit of force to pull. I broke my inertia puller a while back, so out came the RCBS collet puller from yesteryear. The bullets were flat point and hollow point jacketed 158 gr bullets. The powder in the 357s was 3.8 - 3.9 Trail Boss, and in the 38s 3.1 gr. One looked low but it still had 2.8 gr. The powder came out very normal, upside down to dump the powder, no issues, EXCEPT, in several I could see discs of powder in the flash hole, nice and flat, and if I knocked the case upside down on the bench another disc of TB would fall out. Next came primer extraction and examination. The primers looked to be CCI, and under 10X they looked similar to the ones I have. Mine were newer than his, having been bought last year. Then I noticed that some of the primers had 2 to 3 discs of TB stuck in them. The discs would have been pushed into the primer with the decapping pin. I used my 10X loop and a needle to poke the crushed discs out. I also had the decapping pin work loose twice or thrice and get stuck in the flash hole. I found this odd, and upon examination, the cause was the disc that were stuck in the flash hole. To be honest, I've never had to pull a bullet on a TB load, this was the first issue I'd ever had with a Trail Boss load. I'm still pondering the whole deal. I salvaged a big cup of TB, 200 plus primers that I may not use, 200 plus brass, and 200 plus jacketed bullets to play with. Caveat: The method I used to remove the primers is not endorsed by me or anyone that looks like me. Just because I did it doesn't mean you can or should do it. I take responsibility for what I do, and what you do is your responsibility. Anyone else have a similar TB episode or have any ideas. BB

-

Trail Boss is made by ADI in Australia, are you seeing any? Hopefully it's not like in Canada. Powders that were made here got exported to the USA, and then were imported back in. Double tariff sucks.

-

4 5/8 (4 3/4) or 5 1/2 barrel, what's your preference and why?

"Big Boston" replied to Currahee's topic in SASS Wire

A friend of mine mentioned the club, and it seemed intriguing. So much so that I took the trip out to their club and participated. It's in the rolling Saskatchewan landscape with oil wells, cattle and coulees. It is not a SASS club, but they follow all the SASS safety rules. Their rational being that the distances are more what a cowboy on the range would experience. All their targets are oil well casings, the pistol and shotgun targets are about a foot in diameter and somewhere between 18" and 2' in height. The rifle targets look to be bigger. It was fun to shoot with them and the hospitality was great. Their categories were a bit different, but basically a variation on a theme of SASS. A miss being 10 seconds, is incentive to aim a bit more carefully. One strange rule was you were allowed to shoot a gopher if one happened to run into the target area. Their targets remain set up, and they have about eight permanent scenarios, corrals, forts and all sorts of western props. They take their shooting serious, serious fun. I actually sighted in my rifle for 50 yards before going. If you have a flinch, it shows up real quick. One rule I'd never heard before was "The Magic Pellet" rule for the 20 yard shotgun targets. Oft times only a few pellets would hit with a cylinder choked shotgun. In true Saskatchewan form, there were no shade trees, and in the bottom of the coulee where we shot, it was hot. One of the wheels on my cart dropped into a gopher hole and my cart got busted up pretty bad. It was an adventure. We had wind, heat, mosquitoes and a thunder storm, not dull. They call themselves "The Garden Head Cowboy Action Shooting Club", the closest town is Gull Lake, Sask. BB -

4 5/8 (4 3/4) or 5 1/2 barrel, what's your preference and why?

"Big Boston" replied to Currahee's topic in SASS Wire

The 7 1/2" is nice for it's longer sight radius, and on a long match, a bit less fatigue in the wrist. A bit better for long range. One of the clubs out west shoots pistols at 20 yards and the rifle at 50, or so they say. I used my range finder and it's more like 25 and 60. That keeps you on your toes, especially they count a miss at 10 seconds. BTW, shotgun is at 20 as well. I use my 7 1/2s for that. The 4 3/4" or 4 5/8" as nice and handy, just feel right, and most of mine are that. The 5 1/2" ones are for the undecided, neither fair nor foul, just a good gun to have around. I have some of these as well. But let's not forget the 5", as in 1911, perfect in every way. BB -

I've worked on a few 97s, and in my experience they can humble you. I ordered two feed six kits, and they worked fine, without any issues. Even made up one of my own feed six with Model 12 follower. The springs in the kit use less turns per inch and are a bit stiffer. This makes the compressed length a bit shorter. But honestly, any spring seems to work if everything is in order. It's been my experience that you don't need much of a spring either. I usually just drop the spring in with the end cap removed and trim so there's about 6" sticking out. If you load some dummy rounds and load them with the spring removed, they feed as long as the muzzle is pointed up. So I'm thinking you have some other issue. First, do you have the early model left and right cartridge stops or the late model ones. Is you 97 a takedown or solid frame. And just how beat up were they? In the takedown version, if there is too much wear in the magazine interrupted threads, you'll have a neat little gap that can affect feeding. Easy to check, remove the spring and assemble as normal. Now slide your pinky into the tube and feel for a gap. Or just see how much back and forth play is in the tube. Next is to confirm that the interaction between the carrier and the left and right cartridge stops is correct. I find it handy to have a working 97 to compare it to. One nagging point is that both are doing the same thing, which could mean that your assumption that this is just an assembly issue. BTW, it's real easy to have the tube 180º out, ask me how I know. I suppose returning the gun to feed five is an option and then see how that works. Remember, if you only shoot Cowboy, a feed zero works, just use a full length dowell instead of the spring to keep the follower in position, so junk doesn't get into the empty tube. Post some pictures, it may just be something obvious to one of us. BB

-

Every so often I seem to go down some rabbit hole and find it a bit of a challenge to get out of it. My latest rabbit hole looks to be the SxS Coach gun. Being called a Coach gun lead me to assume it was so named because it was the weapon of choice when riding shotgun on a stagecoach. Well, I found out, that was partially true. The SxS was used to defend coaches against highway robbery in England in the late 18th century. By the time stagecoaches were common targets for robbers the SxS was a break open cartridge shotgun, not like the original muzzleloading SxS. Not all "coach" guns were used on stagecoaches. They seemed to be used wherever a deterrent was needed in the prevention of robbery or threats of violence. Looking down the barrels of a SxS shotgun pointed at a ne'er-do-well was likely an effective deterrent. The consequences of misbehaving would be severe. I found this interesting how to write up: https://www.chicagomag.com/city-life/july-2012/annals-of-american-violence-how-to-rob-a-stagecoach/ We use shotguns at pretty near every cowboy action scenario, but it doesn't seem to mimic any particular historical use, unless i'm missing something. There are very few moving targets, we're never ridding in the box of a stagecoach (not very practical, or safe), and only the coffin shaped knock downs have any western mimic to them. I found a movie reference to loading the shell with 18 dimes, but in todays money that would be about $55, so I suspect not many shells were loaded with dimes. The birdshot seems to commonly mentioned and at the time that was likely #6 or #7. Well in that respect, this cowboy is authentic as I load either #6 or 7 1/2. My commercial ammo is 7 1/2 or #8. A bit off topic, but for farmyard work I use mostly 7 1/2 for small vermin and for critters I prefer #2, and #4 when I can't find #2. All my ammo is lead, I haven't transitioned to steel shot yet, and because I practice on reactive targets I don't even want that stuff in my home. Does anyone else have any historic (wild west) coach gun trivia or knowledge to share? BB

-

My take on the barrel length technology and/or theory is that with black powder, a long barrel was an advantage to gain velocity. After that, how well it swings and balance is a factor. On the other end, IMO a barrel can be too short, especially a shortened barrel, one with the choke removed and left true cylinder. At true cylinder, the pattern starts to get large in diameter pretty quickly. The British loved their 21" barrels, and I've found that a 20" to 22" barrel is just about where you want to be and still have a good pattern, especially at Cowboy distances. Recent testing with an experimental buckshot load revealed a decent pattern at 16 yards. All nine 00 Buck pellets were within a 10" circle. The barrel length being 24", true cylinder. A buckshot load falls outside of scope of normal shotgun loads, but as buckshot loads tend to be poor patterning unless buffered, it was a good "proof of concept" experiment. BB

-

The other day while rearranging a few items in the garage I came across a Case Gard 100 with about 90 rounds of reloaded ammunition. Not knowing what they were and not wanting to cut apart a AA hull to find out what they were, they came along to the range. I was the only one at the range, so I set up my typical cowboy layout. I set my steel at 10 yards and at 25 yards. I loaded a mystery shell and let fly at my 10 yard shotgun target. The target did not react as expected, it jumped instead of just moving. A second shot at the berm confirmed my suspicion, had to be the low recoil buckshot that my son and I had loaded up several years ago, more like a decade ago. I then shot several more at my 25 yard rifle targets. Rather a lot of fun actually. In my mind I was trying to convince the mounted bandits chasing my stagecoach to leave us alone. I did not notice any abnormal reaction from the target, just a normal, or slightly harder rifle hit. Given that a coach gun would likely have been loaded with buckshot back in the day, has there ever been any side matches with buckshot? BB

-

SR 4759 was an original powder that could be used safely to duplicate Black Powder velocities. No, not a BP substitute as it is loaded by weight and does not fill the case. Published loads will have to be sourced from older manuals. 8# of SR4759 came my way years ago, I tried to give a few pounds away but nobody I knew wanted it. I did my research and discovered it was a fairly good cast bullet or reduced load powder. If you look back in Speer #9 it has a ST of SR4759 loads. The Lyman #46 also has loads. Before I go further down this rabbit hole, I'll point out that Accurate 5744 will give similar performance for cast loads. It's not exactly a grain for grain substitute, but if you load to the same velocity, it shoots like SR4759. Note: I have limited experience, but the ones I tried worked as predicted in the article I read. IIRC it does leave a bit of dust in the barrel. It just wipes out, so I never worried about it. This is from #48 Lyman, which is in the era where SR4759, 5744, 30-30, 4198 and varget were commonly available powders. Note: Lyman used a Rem 9 1/2 primer which IMO has fairly decent brisance.

-

There are a few clubs/ranges that have a hybrid category that is referred to as "1911 Cowboy". You can shoot it on a normal Cowboy scenario/targets. Instead of two cowboy revolvers you shoot a 1911, two mags with 5 in each, and you can use a Model 12 for a shotgun. Depending on the scenario, the shotgun is either loaded or empty when you come to the line. In Canada we are not allowed to buy handguns anymore, we can still use the ones we have until the government implements a buy back and destroy program. To attract new shooters, clubs/ranges have had to become a bit flexible and innovative with what is allowed. For SASS matches, Cowboy rules are followed. Personally, I find 1911 Cowboy a lot of fun. The 5 in the mag doesn't mess with scenarios and keeps counting your shots simple. BB

-

Most has been covered, so most is repeat with a few added facts, (at least factual from what I've experienced. 1897s of the take down variety only hold 5, they are not far from holding 6, but normal 12 ga factory ammo, 5. I've not worked on any solid frame 1897s. I bought two PV kits and installed them, then they, the 1897 takedown, will hold six. The kit uses a shorter follower, and it looks like a Winchester Model 12 follower. IIRC I had a Model 12 follower and I converted an 1897 to 6 with it. Here's the thing, Model 12 followers are not that easy to buy. The spring in the kit is a bit different, but you can use a stock one. The trick is not how much you cut off, it's how much sticks out of the magazine after you cut it. IMO, after trimming you'll need a minimum of 3" of spring sticking out. Basically what if you have too long a spring, it will be the limiting factor, not the follower. That is why the PV spring is long, but it has fewer coils, IOW the coils are further apart. That way it will compact into the follower. Bottom line, the PV follower is machined, so the inside is smooth and the mouth beveled, it feeds 6 smoothly. If you DIY, it may take a bit of fiddling, especially if the spring is a bit big in overall diameter. Sometime the spring inside an old '97 is not original. All Model 12s hold 6 out of the box, 2 3/4 only, not 3". I don't want someone chiming in that his Model 12 Duck magnum will not hold 6. BTW, the spring length sticking out of the magazine works for lever rifles as well. I have a 1866 Trapper that holds 10, you guessed it, shorter spring. IIRC about 4" out of the tube on that one. Caveat, you are on your own shortening springs, the tube has to be smooth, and the action has to be decent in how it holds the shell in. After all, that last shell out of the tube isn't being pushed very hard. BB

-

Knock down targets are pretty cut and dried, if they go down, they go down, if they don't, they don't. For stationary targets, it gets a bit more scientific, not as scientific as for a game load, but the basics apply. The pattern should be as big as possible at the distance fired, with a pattern dense enough that the hit is visible to the spotters. The pattern should be somewhat even. Shot size is a factor in pattern density, IOW, for the same weight of shot, #9 will produce a pattern significantly denser than with #6s. I prefer #7 1/2, and I use #8 interchangeably. I do not load #9 because, as I said before, I also use my ammo for vermin, and #9s don't have enough energy to get it done. I don't see an issue for cowboy, but if you have a choice, go 7 1/2. This may be a bit of a factor for pop up targets, a large diameter, evenly dense pattern will get you a few more hits. Velocity is a factor for range. If hunting, a 100 fps drop in velocity, will reduce your effective range by several yards. Cowboy targets are generally close enough that 1000 fps is likely sufficient. Here's a little chart I came across in an old publication, it shows the relationship of shot size and weight of shot on effective range. Pattern density and individual pellet energy determine the range. Velocity for lead shot was usually about 1200 fps as a standard. Steel shot is the norm today for hunting, and for steel shot, the velocity limit is higher because steel shot can be driven faster with much degradation in pattern or shot distortion. FYI as steel shot is not allowed for CAS. I've not shot steel targets with steel shot, not even for S&G. I know how a BB gun ricochets, I don't need 50 or more steel pellets bouncing back at me. What I find interesting is how effective 1 5/8 oz of #4s would have been on ducks. The old duck hunters had it dialed. I believe that was what Winchester loaded for their Duck load. For our game, it's fairly obvious that we don't need a 12 gauge, a 28 ga load would likely do well. Which, BTW is exactly what a 3/4 oz 12 ga load will duplicate, with a bit of compromise on pattern due to the respective lengths of the shot columns. But honestly, not much of this applies or should be a concern for our game. We could likely get by in most instances with a 9mm Flobert with its 1/4 oz of #8 shot at 600 fps. At our range a Buckaroo with a 410 does OK on KDs, the Flobert may be a stretch. And before someone starts post rules, yes, I know that 28 gauge, 9mm Flobert, and steel shot are not allowed, they were mentioned for ballistic reference. BB

-

My bad, I assumed that because you did not use a Universal Charge bar that you didn't like it. I had an original one, the aluminum was soft and it never seemed to work smoothly. I tossed it and bought bushings. I have from 10 to 39 inclusive and you are correct, they seldom drop what they say, but I just go to the next size. I use one for 410, mainly so I can adjust the shot by a wee bit, to get a nice crimp. 12 is not near as tiddly as a 410. BB

-

And then the problem was no more. I also have a supply of these green wads, for 1 1/4 loads. A 20 ga nitro wad under the shot, a card over the shot and the rest as before. But this time I used my '97, and it runs cleaner. A bit of soot in the barrel but after 5 shots it is still a bit shiney. Problem solved, no more 3" guns with this load. I can likely skip the over shot wad. Components are a bit hard to get, and shipping is a killer. I've decided to use up my old hoard of components, cowboy targets will not know the difference. BB

-

Thanks, I'll work on the combination. I'm using a MEC 13A bushing and it throws 12.5 gr. I'm using a Winchester HS hull and a AA wad with a card in the bottom to get a good crimp with 1 oz of shot. I've got a good supply of AA wads, I'll use them up. I was testing in a 3" chambered gun, I don't see that making much difference, but I'll test that out. In addition I am using up some old Winchester shot, and it has a lot of graphite coating. I don't think that graphite is getting out of the cup, but it may be. BB

-

I ordered in a jug of Perfect Pattern and loaded up a few, book loads, a wee bit above minimum, because that's what my MEC bushing throws. Everything seems good, recoil, pattern etc. The one exception, it seems dirty. I examined some of the wads and they are black(ish) and the bore of the shotgun is sooty as well. This seems odd, I've run Clays low and it burns well, I've used 700X and it wasn't as dirty. Is this just the nature of the beast? I think I'll chronograph a few to see if they are consistent. I want to borrow my buds Garmin, I don't like shooting shotgun over my screens. BB Addendum: I met my friend at the range and we used his Garmin Xero to chronograph some of my shotshells. First, the Garmin doesn't like to record the speed of shotguns shells. I must have fired 100 rounds, and got perhaps only 20 or so readings. Five shot strings were out of the question, and sometimes it took multiple shots to get one reading. As near as I can tell, the Perfect Pattern load is at 1020 fps, consistent with very little spread. I'm happy with the load. I fired about 100 shells in just over an hour, no bruising, a bit of a flinch after about 50, but was able to concentrate through it. Even tested two slugs, to verify the Xero. Slugs were advertised at 1600 fps, came in at 1560 fps. At 30 yards a hit from a slug sure rang the gong. (The gong survived just fine, My gong, so no comments please.)

-

My 600 is likely the same vintage, it does bridge with #2. #2 is my skunk load, don't need many, I just use the handle of a screw driver to tap the tube. And I'm with you on the Universal charge bar, they are OK on 410, but never liked them on 12/20. BB

-

I use my shells for yard duty on occasion. On small pests, #9 does not kill cleanly. #7 1/2 does, and when I use #8, I don't see much difference on critters. I have some #6 as well, it works for Cowboy as well. Skeet shooters use #9, trap shooters 7 1/2, and the ones that shoot both, they use #8. #9 is not good at trap. But for Cowboy, I'll have to concur, an ounce is an ounce. As far as ricochet, IDK which tends to bounce back the most. BB

-

I had a few 45s, and the staff at mansons were very helpful. The put together a kit and ran through the procedure with me. I did them all, and i'd rate their tools as very nice. Skill level required, some experience with reamers a plus. Some of my cylinder throats were rather oval shaped, the reamer only touched about 2/3 of the throat. Much rounder now. If you only have one to do, find a smith. But, I don't know what a cylinder reaming costs. The tools weren't exactly cheap.

-

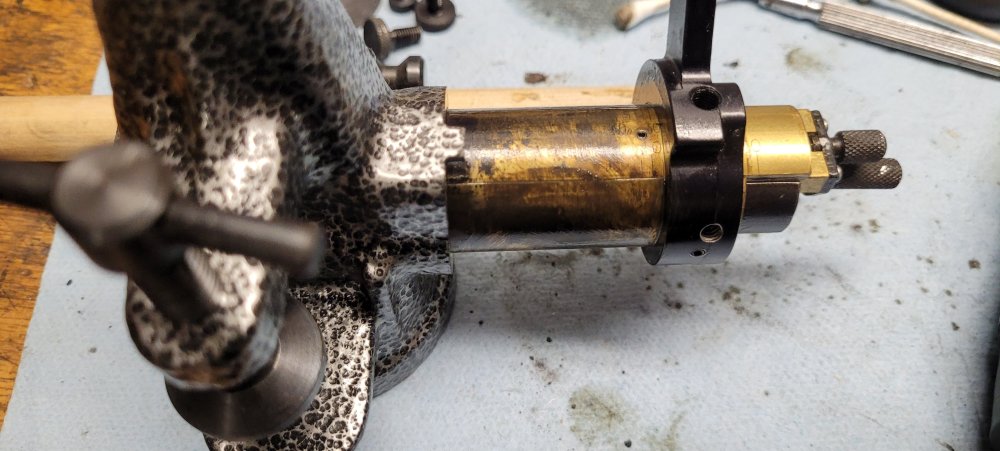

Lyman 55, My DIY conversion to black powder.

"Big Boston" replied to "Big Boston"'s topic in SASS Wire

Fixing someone else's or even your own neglect can be a challenge. Part of the issue was Black Powder, the other was it likely sat that way for many years. My approach was to minimize any further damage. Although Ballistol is not the best penetrant, my thought was that I wanted something inert, no sulfurs or anything else, just oil. I like the ATF and acetone idea, I have an engine with stuck rings, I'll use some on it. I reviewed the process after I was done, and the Ballistol had reached all the surface. The iron body had the most corrosion, rust was very thick. It took about 4 applications of Gel Rust remover to get it out. The rust was hard enough, and very abrasive. I was checking with each step and stopped when the brass would not scratch anymore. I have to say, black powder is one nasty substance. Any moisture and it comes alive, and tries to kill everything in sight. I hope there won't be a next time. BB -

WW AA wad data.pdf Used the last wad and was going to recycle the box, then I noticed the data. I still have several #s of 452. BB

-

Lyman 55, My DIY conversion to black powder.

"Big Boston" replied to "Big Boston"'s topic in SASS Wire

I'm beginning to realize life is a never ending story. Just when you think that you've finished a project, you go to a gunshow and find a Lyman 55 Black Powder measure, complete with a Lyman powder measure stand. I noticed it immediately, first walk by the vendors table. He did not have prices on his goods, but he did have a price sheet on him. I asked, he said $60, I said "SOLD". As I would find out later, I made a mistake, the price was good, and in my haste to make the deal, I'd bypassed the complete inspection part. It looked nice, it was all there, but when I got it home, I discovered I could not turn the handle, it was locked up solid. It was already well after supper, but I had to see what was going on. I removed the tape holding the lid on the reservoir and black powder poured out, about 50 or so grains. I screwed off the reservoir and looked down at rust on the iron parts and black crud on the brass. After about an hour of soaking with ballistol it still would not budge, not even a bit. After trying a few things I realized this would need some serious attention. Out came the hammer and a wooden dowel to use as a punch. It took a bit of wailing, but the drum came out. What a mess. I began the clean-up, made some progress, but it was way past my bed time. Fast forward to a new day. After several hours, 0000 steel wool, rust remover, 1000 grit emery, half a roll of blue towels, Iso, and some Autosol, It was ready to reassemble. I don't tend to do before pictures, I seem to focus on what it is when I'm finished. I did loose a bit of definition on the position marks, they were a little faint to begin with, but they are still visible, they are lost in the picture (glare). You can still make out a bit of discoloration inside the powder measure body, and few good pits in the baffle. Removing those is do-able, but functionally not necessary, and IMO is just extra work for nothing. I've bought a few of these, they all have flaws, the nature of the beast. This one, in addition to the corrosion issues, had a short measuring cylinder, and needed a 0.010" brass shim under the side end plate. The drop tube also needed a good brushing inside, no corrosion, just black discoloration. There they are, with the recent gunshow purchase on the far right. I've sourced a Pedersoli 45-110 Sharps, it may have to come home. BB ADDENDUM: I remembered just before getting the measuring cylinder out of the body it took this picture. -

"It would be impossible to estimate how many bullseye competitions have been won with 2.7 to 3.0 grains of Bullseye under a 148 grain .38 Special wadcutter bullet. Of course, that deeply seated wadcutter bullet reduces volume inside the cartridge, so the dynamics of a more conventionally seated bullet are a bit different." Worth repeating. I have more 452 powder than Bullseye, and I shoot wadcutters with about the same weight of it. A good load for my pistols, and I load a different load for my rifles. I've posted before on this but something tweaked my memory. Bullseye is too position sensitive to be used with a light RNFP bullet. There is too much air space, load density too low. You can expect about 50 fps between the 2 positions (powder against the bullet vs powder against the primer. However, with powder against the primer, Es/Sd numbers are good. BB