-

Posts

11,968 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Everything posted by Garrison Joe, SASS #60708

-

A blast of air once you finish with your solvent of choice, yeah. Get the final droplets out of there. But before cleaning? No useful purpose that I know of - BP residue is not going to just blow out of a gun. good luck, GJ

-

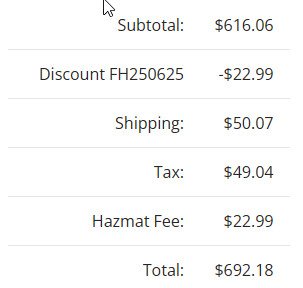

Primer sale at Natchez plus free Hazmat

Garrison Joe, SASS #60708 replied to Abilene, SASS # 27489's topic in SASS Wire

Take a close look at the price add-up. I ordered Hazmat materials 2 weeks ago. The Hazmat price shows right at the bottom in the price add-up , but at the top the hazmat charge gets taken off as a discount. Shipping is a separate charge, and yes, shipping is higher than it used to be several years ago! So, if you have given them the "FH" code in the "coupon code number" box during checkout, and the date is still valid for that particular code, you should get the Free Hazmat discount. If not, call them! They are very pleasant to talk with! good luck, GJ -

When you order a slide hook, also find a high-strength tool steel slide hook screw. If the factory screw breaks below the threads, it often requires drilling the action from the outside, blind, to get to the tip of the screw and remove it before you can get past the slide hook part of the disassembly. Here's a great one, and I use them in all my 97s https://the-online-outpost-licensing-corporation.myshopify.com/collections/shotgun/products/copy-of-1897-winchester-norinco-iac-shotgun-action-slide-hook-screw-by-the-smith-shop-97 good luck, GJ

-

Yep, I put one of those light firing pin extensions in my WB rifle. It lasted 2 years, then the front end of the FPE broke apart during a match, about 8 months ago. Symptoms - one or two light strikes per 10 rounds. A small steel chunk about the size of a BB shot broke off and bounced around between the remaining part of the FPE and the large end of the firing pin or, when it did not fire, the broken piece slammed against the bolt. You can spot a hollow FPE due to it's weight is half normal, and one end has been bored out for most of the length, and a press fitting slug of steel has been presssed in and profiled to the rest of the pin surface. So, a slight ring shows in the end that has been bored out. No, I don't have it still to show you all a picture, but I will NEVER use a hollowed out FPE again. good luck, GJ

-

There are many ways to clean BP residue which work. So, I doubt there was really a need to My favorite is a 1-1-1 mix of hydrogen Peroxide. rubbing Alcohol, and Murphy's oil soap (abbreviated PAM). It also cleans greasy kitchen appliances. Some folks do NOT like the smell of Ballistol - had an ex or two in that camp. PAM - they liked the smell. It's a lot cheaper to make than a 1-1 mix of Ballistol cleaning solution. Works without warming it up as well. good luck, GJ

-

Almost sounds like the previous owner may have tried to reassemble the gun and gotten something wrong. Could be why it was sold after only a few number of rounds fired. Shame on the seller (a gun shop?) for selling the gun when it won't cycle, if that is how this situation turns out. Nate Kiowa Jones is a good cowboy gun smith who may be close to you in East Texas. I've been very pleased with his work, but do ask about how long before he can get to it. Nate Kiowa Jones, Steve Young, Steve's Gunz, Lampasas, TX (512) 564-1015 Boomstick Jay is also a very great hand with cowboy guns - Well, don't need this again, Nate Kiowa Jones, Steve Young, Steve's Gunz, Lampasas, TX (512) 564-1015 How about: Boomstick Jay, Jason Widmer, Boomstick Arms Co LLC, Leonard, TX 254-368-4540 good luck, GJ

-

Yep, I have had that bolt screw back out, but it only stopped forward motion of the bolt. Put a drop of blue locktite on the threads to retain it. That is a medium strength retaining fluid and can be disassembled with normal tools when needed. OP - Realize that all the screws in this gun are special - metric sizes and many are small and have odd shapes - such that buying something to fill a missing screw hole and work properly - is a real PAIN. good luck, GJ

-

My response was, in part: What part of the IF at the beginning of my statement did not come through the wire? As is always true on any "help forum" - the responses depend upon exactly how much and how accurately you can tell someone a thousand miles away who does not see and hear you running the gun, enough info to spot your problem. And often, you are telling folks only what you already know, not about the things you don't realize you are doing or are going on in the gun or ammo. Run a test - take 20 or 40 rounds, and intentionally run them slowly through your gun. If you get no light strikes - then running at your normal match speed really is contributing to your light strikes - it's about you. If you get one or two light strikes, it's about the gun - something in there slows down the firing pin strike. Often it's hammer spring (mainspring), but it can ALSO often be due to: * a dirty firing pin channel, * a broken firing pin, * a broken firing pin extension, * the commonly mentioned weak mainspring, * dirty gun, * hammer dragging on the frame or even your thumb, * primers not fully seated (at this point in this list, everything I have mentioned I have had happen in my 73 rifles), or even a bad lot of primers. And there's many more potential root causes. So, although a weak mainspring is a very common "jump to" conclusion - I find it really does not happen very often unless you have had a gunsmith modify a spring to lighten it up beyond reasonable limits. So, I don't trust just jumping to the conclusion you seem to be betting on. Maybe it is right, maybe it's not - and you will buy a part you don't need to replace (at this time). I run '73 mainsprings for about 10 years (with 5,000 rounds fired a year) before I ever start to worry about them getting weak. All I can really tell right now - you probably have not done enough diagnosis to really find the problem. good luck, GJ

-

Ummm, if you are intentionally trying to go faster recently, you could now be pulling trigger while the action is not quite closed. Try running with this in your mind: "Lever closed, then trigger pull!" I got to that point and had to work much harder to avoid what looked like light strikes, but they were just standard strikes while the action was finishing chambering the round, at that point, the FP cannot reach the primer solidly, so you get the minor dents on the primer. good luck, GJ

-

Perfect Pattern is VERY dense. It's hard to fill shotshells up to make a good crimp. But, I have shot Remington STS, Nitros, Gun Clubs with about 14 grains of PP, 7/8 ounce shot, a 3/4 ounce CB0175 wad and most any primer. Low pressure, low recoil. Adjust until you can make a good load, ,but you will probably have the wad just sitting on the powder, or even floating a little, which Hodgdon techs have said is just fine to do (just be careful not to push the wad stack down too deep as you apply final crimp). That CB0175 wad takes up about as much room as any 12 gauge wad on the market, so it's great for Perfect Pattern loading. Powder should work fine in .38 specials, about same as you dropped with Clays, but I no longer load .38 special to even test it out. YMMV, but these are light loads and should be no pressure problems. good luck, GJ

-

Yeah, sometimes our old hands around here forget how hard NOW it is to get some of the powders they recommend! For a powder that will work in .45 Colt light loads, and is available, TiteGroup is hard to beat. Other than the fact it smokes up (lays down soot) cases a little more than most powders, especially the .45 Colt case which is very thick walled and rarely seals up the chamber really well with light cowboy type loads. good luck, GJ

-

New to SASS need some reloading help

Garrison Joe, SASS #60708 replied to Dragon1976's topic in SASS Wire

I've loaded a ton of 12 gauge shotshells with WST. It was originally designed as a shotgun powder, replacing Win 452AA powder about 1985 or so. So, it will make great light 12 gauge loads if that is what you were able to find on the shelf. Although it is just about perfect as well in .45 auto loads. good luck, GJ Yes, loading shotshells is a WHOLE lot different than loading cartridges. Especially when you start using plastic hulls with a folded crimp. Which most folks eventually go to due to faster reloading on a shotshell press and much cheaper cost for the hulls (almost free if you hunt down hulls at a shotgun range). GJ -

What are you using for your current .45 Colt cowboy reloads? Most likely that will be appropriate for the open tops, as well. good luck, GJ

-

New to SASS need some reloading help

Garrison Joe, SASS #60708 replied to Dragon1976's topic in SASS Wire

TiteGroup will work for all that. A faster burn rate than HS-6 and thus will be cleaner and more consistent in light loads. Commonly available right now, too. good luck, GJ -

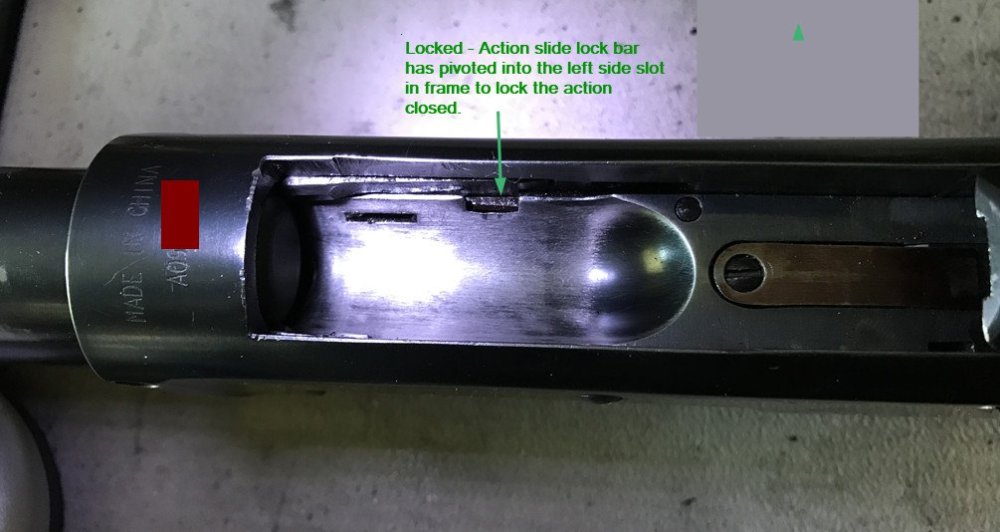

"Pull the thread" meaning you should dig deeper into the problem that even the lock release button does not release the action lock. Not "look for some other wire post that covered this problem." Although a search of the SASS wire forum might a way to learn more about possible causes of the problem. Be aware that the search engine that the forum software provides (at the top of the forum page) is not a very easy way to find old posts. Here's a more powerful way to search - use Google. In the address bar of your web page, type something like this for an "address" "sassnet: 97 action slide locked" You will get a whole bunch of results that apply to some of the problems with the action slide lock not unlocking at the right time. It could be really useful to you to scan through some of these posts from about 2012 to the present. You have a condition where neither of the normal ways of getting the action lock to unlock and let the action cycle are working - the forward push on the forearm, and the push on the release button. Here's some pictures of what should be happening. This shows one Chinese 97 that works well. You will have to look carefully with good light to see how your gun compares. First, when the action is open, you should see on the left side of the carrier three (of the six) parts that make up the lock system: the slide lock bar, the leaf spring that causes the bar to normally be tipped out away from the carrier surface, and the screw which holds the spring in place. Push gently on the left end of the lock bar and you should see it move into flush with the side of the carrier block. The action slide bar works like this..... When the action needs to be locked, the action slide lock (bar) pivots out into a slot inside the left side of the receiver. In an emergency unintended lockup, it SHOULD be possible to slip a small flat-bladed screw driver in this slot, catch the edge of the locking bar and pivot the bar to the unlocked position (bar pulled into the carrier.) Be very careful not to cause a round to fire if you do this! When the action should unlock and let you run the action normally (such as after firing), the bar is forced into a position flush with the left side of the carrier. There is a small slot milled in the left side of the carrier which lets you see the position of the bar. This unlocks the action so that the slide can be pumped open. When should action lock be locked - with action closed and hammer cocked or hammer in the half-cock notch. This means the gun will not "blow open" when the round fires. This locking on the half-cock hammer position is a problem unwary shooters have when they lower the hammer during loading, but fail to lower it fully to rest on the firing pin. This locks the gun when shooter first attempts to cycle the action to fire the 97 on the line. When should action be unlocked - after firing a round (due to recoil), after pushing forward on the forearm of a closed action with hammer down, or while pushing the slide lock release button with the action closed and hammer down. Also, whenever the gun action is open (the auto-pivoting of the lock bar away from the carrier surface when the carrier is exposed below the frame takes care of this). Maybe you need to tell us the context of how this problem started to occur. Is this a new gun to you, and has it shown this problem from the beginning? Is this a problem that has occurred recently, after working well for a while? Did this problem begin AFTER you did a major disassembly and reassembly of the gun? It's pretty easy to assemble the gun so it mostly works but the slide lock does not. good luck, GJ

-

Well, pull the thread on why that does not work, and you will probably find the root cause. The action (un)lock button should be "depress-able" with the hammer down on a closed action. That is how you unload a loaded 97 - you press the unlock button and pull the slide open. GJ

-

Bore Sighting

Garrison Joe, SASS #60708 replied to Capt Stephen D Hill, SASS #56151's topic in SASS Wire

I don't use a boresighter light. I (like many others) just use the "sight down the bore" approach. Get some sandbags or other rest. But, I've not seen a reason to even do that with SASS MATCH guns. No need to get within 1/4 MOA of the aim point. And, with iron sights, you really have to SHOOT the gun anyway. It's not like sighting in a scope where you can twist a couple of knobs and get the crosshairs onto the laser dot. I did barrel-boresight once (yes, through the .45 caliber hole) a Winchester clone High Wall just to get my tang sight close to POI, though. That probably saved me 3 shots. Ho-hum! 😃 GJ -

A 97 is not a black gun where you can just toss in new parts and they work (due to tight tolerances now), instead of how guns were designed 125 years ago (requiring a lot of hand fitting). Throwing new parts in it can often be more work than fixing what is wrong. First, diagnose. Second, find a way to fix the problem with some smithing. New parts for a Chinese made 97 or 93/97 can be real hard to get, and can often need the same fitting that you would do if you just tuned your existing part(s). Be glad you have Outlaw Gambler to refer a parts order to. I've gotten several 97s to open better, and tuning the slide lock itself was rarely what it took. More likely, it's how the diamond shaped tab at the rear end of the action slide engages the action lock. Does the action lock button on the right side of the action operate the action lock to release it and open the action when you have "hammer-down, action-closed" condition? This will tell you more about what "hidden part" in your gun is not working well. Here's a manual with a good diagram of a 97..... https://www.cimarron-firearms.com/Manuals-Forms/PDFs/1897Shotgun.pdf Do your testing actually firing rounds. Diagnosing this with dummy rounds is hard for a beginner smith. Kinda sounds like a good smith would be the "part" you need to find, IME. If you have some time to wait, Squibber does a lot of 97 work - he's in Casa Grande AZ. https://www.dustybunch.com/ Outlaw Gambler is great, too. But, a little farther from you. good luck, GJ

-

Already answered that, it's the action slide lock. Which is forced to open with either 1 - recoil of a fired round 2- shooter pushing forward on the slide (forearm) 3 - pressing the action lock release button Read answers, get answers. good luck, GJ

-

Ejection failures - things to check Open action briskly ("run it like you stole it") Check ejector (a small 90 degree angle spring on left side of action ) that it is intact and not bent badly Check for both extractors are free to work (not gummed up) and that the tail is not broken off the left side extractor. As for the "action doesn't like to open unless you have fired a shell" - that is what Browning designed the gun to do. The action slide lock was designed to keep a dud shell in the chamber for a second or so instead of the shell deciding to fire as shooter ejected the dud. Back when primers did not fire off every single shell instantly (before 1920), this was seen as necessary. Now, not so much. As you put some wear into the gun by using it, you will find the slide lock opens much more easily. But, if it is getting in your way, a good 97 smith can polish it up and reshape the lock actuator hook to work smoother. good luck, GJ

-

Progressive Shot Shell Reloader’s

Garrison Joe, SASS #60708 replied to Lefty Vaquero #39185's topic in SASS Wire

Right in the manual for the 366 are the instructions of how to adjust the auto-advance. The $6 pawl (which is the hand that pushes the shell plate to next station) is replaceable in 5 minutes, as well, when it wears the pawl tip down. I've run Lee whack-a-moles, a Bair, Mecs of several types, an RCBS MiniGrand and now have two Hornady 366s which load up to 2000 rounds a month. Downside - A used 366 will only last you about 50 years (if you don't maintain it). 😄So, hunt down a used one and save $800. Hornady continues to make parts that will be shipped to you in 3 days to fit any 366 ever made. It's so hard to compare the customer service on the 366 to other machines due to the longevity of that 366 model soldiering on with minimal parts required. All progressives have a learning curve. Most progressives need careful adjustment periodically. Put a spilled shot and powder collection pan under ANY progressive you use. You will thank yourself many times over. I find the 366 to be the simplest progressive to run and to adjust. And, adjusted properly, it makes a better-than- factory looking shell. good luck, GJ -

Uberti/cimmaron 1873 reloading help

Garrison Joe, SASS #60708 replied to Bowtie747's topic in SASS Wire

The toggle link rifles "bounce" a feeding cartridge around, since the carrier is more like a tray than a clamp as it moves cartridges from the magazine to the chamber. That lack of positive control means a semi-wadcutter bullet with it's sharp land just behind the nose can catch on the sharp edge of the toggle link guns' chamber. Jam. Now then, a full round nose (RN) bullet, might seem like a great idea, but it can (rarely) result in a round firing in the magazine, if the round tip can contact the primer in the cartridge ahead, and there is some sort of strong jarring motion that builds some inertia in the stack of cartridges. Like dropping a loaded rifle, or letting the Win 1860 rifle's spring loaded cartridge follower loose through carelessness when loading. So, two bullet designs are real practical for toggle link rifles. The Round Nose Flat Point (RNFP) bullet design has a lot of fans. A blunt tip for safety, no sharp land to catch on the chamber. Has been the conventional shape for bullets used in a lever rifle for ages. But, it's got a shorter nose design than the other practical competitor. The Truncated Cone (TC) bullet is the other design that works well. Also has a blunt tip for safety, and no sharp land on the bullet. It can have a longer nose than the RNFP does for the same weight of the slug. Longer nose? Why does someone want that? As bullet weights get driven lighter and lighter (a popular weight now for .38 special is the 105 grain bullet), it becomes necessary to pay attention to the overall length of the loaded cartridge, because each toggle link gun has a minimum length of cartridge that it can feed without jamming. Due to the design of the carrier (and no moving cartridge stops to keep upcoming rounds in the magazine), too short a cartridge length lets one cartridge into the carrier, and part of the second cartridge into the carrier, too. But, shearing a cartridge into two pieces by a carrier which has an upward shear motion as it raises the first cartridge up to the chamber - would be a real bad idea. So, real light bullets benefit from using the TC design since the bullet nose can be tapered more, putting less lead in the nose and more lead in the body of the slug, giving the bullet more length, letting you make a longer cartridge in a .38 special case.. And, the bullet weight you started with, 158 grains, may have been realistic for defense ammunition in revolvers back in the 1920s, but it's way too heavy for use in SASS matches which reward accurate-enough shots fired at maximum rate of fire. A 125 or 105 grain slug makes a lot of sense right now, both in rifles and revolvers. And most bullet casters can supply those. (I assume you are interested in shooting cowboy matches, since you posted to our forum). I'll leave it to others to tell you of suppliers around the Northeast. I'm a "fur piece" from there, and cast my own anyways. good luck, GJ -

Cataract surgery: does it affect shooting?

Garrison Joe, SASS #60708 replied to Tell Sackett SASS 18436's topic in SASS Wire

Depends a bunch on just how bad the right eye is. If you currently can get it "20-20" (or close) with a good lens in your glasses, then you probably can get the right eye surgery to do just as good a job. Ask your Doc who is going to do the lens replacement for sure. If you have astigmatism in one or both eyes, realize that could be corrected with the new implants, but it's about twice as expensive and insurance is reluctant to cover that extra cost. I had cataract surgery, one eye then the other, about 20 years ago. I had both eyes set for close distance because I had been myopic all my life. Now, I wish I had just had distance correction lenses put in. Might have been able to drive and shoot and watch tv without correction, and just use glasses as readers and for computer work. I would not recommend the split distances on the lens settings, it will cut your peripheral vision down. But, I have strong astigmatism in one eye, would not have paid extra for the implants because my history is the astigmatism SHIFTS angle every couple of years, and I still would have needed glasses to shoot and drive even with distance implants put in. Sigh. After surgery, I surely saw better than with the cataracts. Saw COLORS again, too. Unless the surgery goes badly, you will have little problem with any of those activities. Rest up after surgery as prescribed by your surgeon. It IS worth it to find a GOOD cataract surgeon. Not just a small town eye doctor. good luck, GJ -

SAAMI chamber specs show the chamber could be best cut with a 0.459" straight reamer. Technically, the chamber should taper 0.001" to be 0.458" at the mouth of the case. But chamber tolerances would allow up to a 0.463" straight reamer cut. SAAMI handgun specifications; go to page 47 for the dimensional drawings of chamber good luck, GJ