-

Posts

3,030 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Chief Rick

-

-

It appears I was mistaken on streaming - YouTube is streaming the race on the INDYCAR on FOX channel

EDIT: Only showed first 10 laps live.😒

Guess I'll go reload.

-

1

1

-

2

2

-

-

I used to.

Don't have regular TV channels and no way to watch it streaming that I'm a ware of (and I'm not willing to pay to watch it).

-

4 hours ago, Cyrus Cassidy #45437 said:

Mrs. Cassidy and I went out geocaching from horseback, and it was rather fun. Geocaching has a lot of games and contests associated with it, and so does ham radio. It got me to thinking I should develop a geocaching from horseback with ham radios game. Any ideas?

Maybe POTA or SOTA on 10M it that's possible on your area.

Mobile radio, small lithium battery and ~33 feet of wire.

-

2 hours ago, The Original Lumpy Gritz said:

What questions were there on the Posse Marshall walk thru on this stage?

None. Only two posse's.

This stage was also shot last month (with a change in target numbers and sequence) two see it any unintended problems would come up.

-

1

1

-

-

41 minutes ago, El Sobrante Kid said:

"Would you change the instructions?" Well... that depends on what you want to accomplish. First, I agree with the other comments that the shooter is fully responsible for the error. That said, after reading many comments over the years that are generally along the lines of, "Benefit of the doubt..." and "Don't create P traps", etc., the overall sentiment that comes across is to not unnecessarily create any problems for the shooter. What kind of a stage do you want to create? If you want to reduce the risk of an accident as much as possible, I would change the instructions. If you want to have a stage with some additional level of risk of an accident like this, leave the wording as it is.

I'm going to go on a tangent to my own thread...

If the competitor had been in a rush to put the rifle in the vertical rack and dropped it, would you then mandate all other shooters to carry the rifle down range?

"Benefit of the doubt" and "don't create p traps" has nothing to do with safety.

Allowing a competitor to re-stage a long gun vertically or carry it downrange has no specific tendency to necessarily create a problem for a shooter, but mandating one or the other could very well.

-

1

1

-

1

1

-

-

31 minutes ago, John Kloehr said:

Taking these words at face value, the poor competitor klutzed it up. No change needed.

In the event of a respectful appeal, was the platform step to the ground really big and did it happen right when getting off the platform? Just asking to make sure. If this happened while simply walking... "Safe for movement" is otherwise clearly spelled out for both long guns and revolvers.

No. This happened after the competitor was on level ground. This platform has a ramp, not steps, to get to ground level.

-

Stage has downrange movement. Shotgun and rifle shot from platform/deck.

Shotgun shot first and restaged at position.

Rifle shot second and shooter has choice making rifle safe in vertical rack (to allow for safe downrange movement) or carrying rifle downrange and making rifle safe on table placed at pistol shooting position.

First shooter of the day chooses to carry rifle downrange.

While doing so, he catches his revolver grip and pulls a loaded revolver out of leather - dropped loaded gun = MDQ.

There were no environmental factors or gear failures playing into this.

Would you change the stage instructions to make all shooters make the rifle safe in the vertical rack or leave it shooters choice?

-

On 5/12/2025 at 12:28 PM, El Sobrante Kid said:

Related to the use of tablets for scoring; has anyone found that one particular tablet is easier to use in bright sunshine? Some of the tablet screens are almost impossible to use in direct sunlight.

It's been my experience that the Kindle Fire tablets (currently using Fire HD 10) have no problems in bright light and also have good battery life.

You can also get the child friendly case with carry handle to protect it.

We have two tablets running PractiScore that are also sync'd to Bluetooth timers. TO still calls out time, but the score keeper only has to push a button to import the time directly from the shot timer. One less chance for an error.

-

4

4

-

1

1

-

-

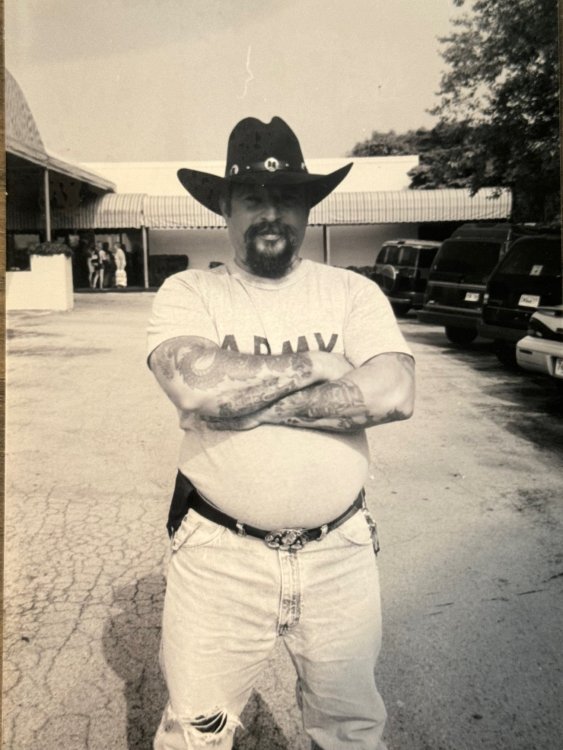

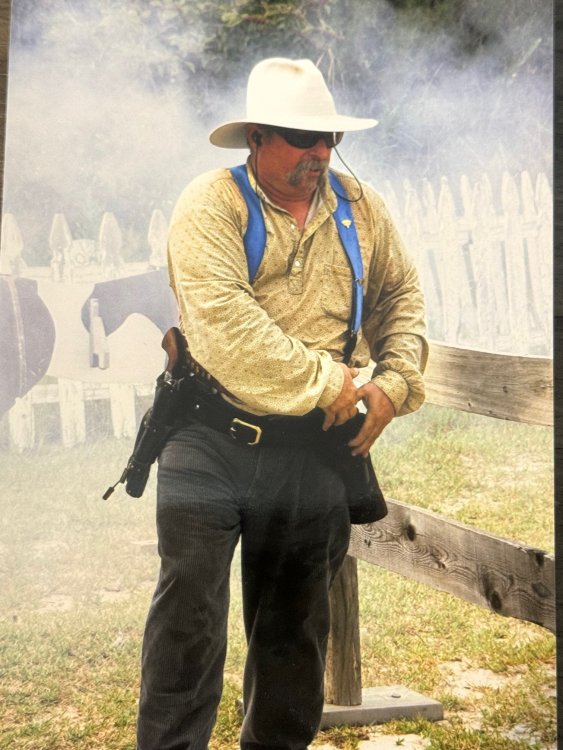

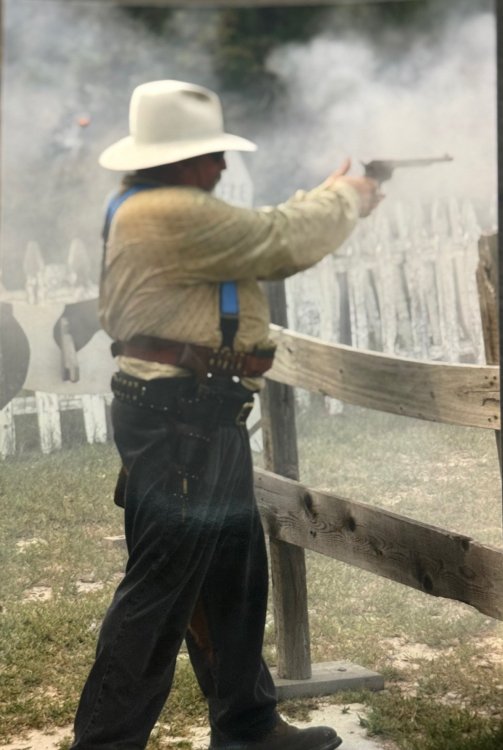

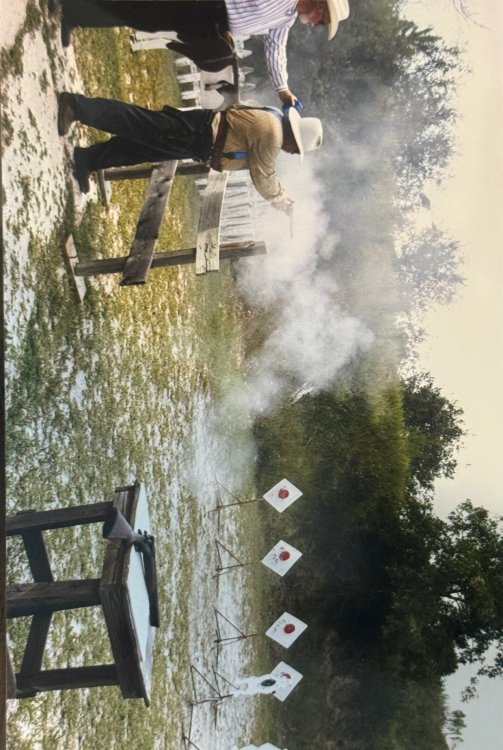

Richard (Hawg Runner) Craparotta of Collins MS passed away on May 7, 2025, in Weeki Wachee, Florida at the home of his daughter with family. Born on January 16, 1951, in Brooklyn, New York, Richard lived a life marked by passion, dedication, and a deep connection to the things he loved.

Richard was the beloved child of Catherine and Angelo Craparotta, both of whom preceded him in death. He will be remembered with love by his daughter Christine Gregory and son-in-law Gregory Russell. Richard also leaves behind two cherished grandchildren, Christopher Olson (Marina) and Catherine Gregory. His memory will be held close by his sisters Michelle DiBenedetto and Leanora Chiaruttini (John).

Throughout his life, Richard found joy and camaraderie in motorcycle riding and shooting sports. He was an active participant in the Mississippi Peacemakers and the Single Action Shooting Society (SASS), communities that reflected his adventurous spirit and appreciation for tradition.

May Richard’s memory bring comfort to those who knew him and continue to inspire stories shared among family and friends. A Visitation will be held on May 15, 2025, from 04:00 PM to 06:00 PM at Dobies Funeral Home, 9944 Hudson Ave, Hudson FL 34667.-

1

1

-

-

-

8 hours ago, watab kid said:

perhaps ill look into that , i have family in iowa and i think a friend from the old gunsites i used to visit is heavily into this , i might reach out a see what it might entail , been a long time since we spoke but im sure he might help me if i ask ,

There are a couple of YouTube channels that have recordings of Technician and General classes. Watch and rewatch those, and do one of the free ham study tests online and you'll have you're license in no time.

I can try to link the ones I used when I get home tonight.

-

3 hours ago, Stump Water said:

Just another extra something in the gun cart that wasn't really needed.

Maybe for you.

Some people have medical conditions that make traditional loading difficult to impossible, especially over long days.

-

POTA doesn't have to be QRP.

I have a Yaesu FT891 and was playing with an EFHW from the range after our monthly matches.

I'd really like to build a linked dipole out of lightweight wire.

-

1

1

-

-

2 hours ago, Rye Miles #13621 said:

Fans around him were saying he was plastered🙄Is there not some responsibility on the part of fans to behave?

I can see a lawsuit where the inebriated or his family sues the stadium and/or vending company saying they should not have served him enough alcohol to get "that" inebriated.

-

2

2

-

-

1 hour ago, Stump Water said:

Good stuff.

I'm guessing Hornady.

Based in my limited experience with 6.5C - absolutely not.

Alpha perhaps.

-

1

1

-

-

Best wishes for safe travels.

Looking forward to having you setting up shop and shooting with us in MS.

-

5 hours ago, Diamond Jake said:

We sometimes have a popper as one of our mandatory SG shots, no bonus, but a static plate for the typical SG "shoot until all targets are down".

I like that a lot more than stages calling to shoot a 12" hose "snake" until it's out of a circle or across a line. after a few shooters the hole in the ground is so deep the snakes often hide in there and don't come out.

Our snakes are garden hoses with heavy wire in them so they sit up "coiled". They are put on stumps and you have to shoot them off.

If clubs are not already doing this and plan to start, be advised that the hose collects shot and can get very heavy. They need to be checked and changed out periodically.

-

1

1

-

1

1

-

-

We have one stage that has a clay thrower and it throws fairly consistently.

We've had several serious discussions at our club on shotgun make-ups. I am for them.

If we have 15 shooters there's probably only three that have a background of shooting clays or actually hunting fowl.

There are also several variables for both poppers and machines that throw clays. I've seen clays break when the machine/popper is actuated. Do you give the shooter a reshoot for prop failure or give them credit for "breaking" the clay? I wouldn't want this to be a factor that determines placement in a state or higher match.

For our annual, I will use the clay thrower. The bird must be engaged but if it's missed, it doesn't count as a miss. If the clay is busted, the shooters name goes in for a random drawing after the match.

-

4

4

-

-

A shooter shoots the shotgun (in this case, Win '97), opens and shucks the empty hull, then starts moving towards the next shooting position with shotgun in hand. While moving to the next position the action on the shotgun closes. The shooter pulls the trigger mid-step, dropping the hammer while continuously moving. The shooter waits until they are at the next shooting position to open the shotgun, reload and shoot the next two shotgun targets.

What's the call?

-

Unless you are going for a specific look, I recommend chinks.

Chinks can be worn year round.

I don't find them very uncomfortable in the high temp/high humidity summer and they offer a small amount of extra comfort in the cold.

-

1

1

-

-

My notes show I was using 5.0 gr.

I don't remember how light that was and didn't have a chrono at that time.

-

1

1

-

-

6 hours ago, Sedalia Dave said:

That controller is vary affordable however, reading the critical reviews on Amazon gives me pause.

For any solar charge controller, I would definitely buy one rated for at least twice the wattage of my solar panels. This is because most charge controllers tend to overheat when operated close to their rated wattage.

What controller are you referring to?

-

I have a Litime 12V 50Ah LiFePO4. Currently $220 on Amazon and includes a charger.

Has run my FT-891 for several hours during field day.

I also have an older Jackery and two of the Jackery solar panels.

What I need to do is buy a MPPT solar charge controller do I can charge this Litime battery. Suggestions?

-

1

1

-

-

On 3/19/2025 at 7:52 PM, Rye Miles #13621 said:

Yea but the Dragon spacecraft didn’t land near Houston it landed 23 miles from Tallahassee. It’s just giving people an estimate of the location of the landing. No big deal!

Let's agree to disagree.

Next time you want to go somewhere and end up ~20 miles off because the landmark given is just an estimate of your final destination just remember, it's "no big deal".

Sorry, but as a former sailor I have some pretty set ideas of what a coast is. The American society doesn't need to be dumbed down any more than it already is.

-

1

1

-

Progressive Shot Shell Reloader’s

in SASS Wire

Posted

Just curious, how many rounds do you plan on reloading at a time? In a month? In a year?

I ask because I thought I needed a progressive press. I load anywhere from three to six boxes a month, depending on the month.

I bought a used Ponsness-Warren that was set up and ready to go. It made beautiful loads (I only used AA hulls) until I let the machine get a way from me. The amount of time that it took me to straighten out the machine more than eclipsed what it would have taken me to just load them all on my MEC Sizemaster.

I'm back to using my MEC Sizemaster.