-

Posts

11,947 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Posts posted by Garrison Joe, SASS #60708

-

-

Main reason the top latch is loose is someone shot heavier loads than the latch was made to handle - commonly factory loaded smokeless loads made for later model pocket pistols. The first and second gen IJs were made for black powder ONLY! The LONG entry into the cylinder locking slot proves this was a black powder gun. Repairing the loose latch problem usually well exceeds the value of the gun, especially now that the gun has been out of production for over 100 years and parts have to be made or salvaged off another gun..

The usual answer for your problem is to buy another pocket pistol, but this time you know how important it is to check the top latch and trigger function.

Unless you are good with shooting and cleaning after black powder loads, you should look for a 3rd generation IJ (which will probably be twice the price of an older IJ).

good luck, GJ

-

1

1

-

-

53 minutes ago, Marlin Schofield said:

originals designed/made by the late "Wild Bill Brody",

Think that would be the late, great Wild Bodie Tom.

Like here:

Wild Bodie Tom load-6 kit made by Palo Verde

good luck, GJ

-

1

1

-

-

10 hours ago, Abe E.S. Corpus SASS #87667 said:

IMR Target was the answer to Alliant Bullseye and there was another “Dot” (Blue, I think).

The complete set of "color" powders that IMR produced for a few years were:

Red - a 12 gauge target shotshell powder, also useful for target pistol loads

Green - a 12 gauge (field) and 20 gauge powder - like Green Dot

Blue - a magnum load powder like Blue Dot

good luck, GJ

-

1

1

-

-

If you are loading typical cowboy type loads and using "Red Dot low end charge weights" - you will not have high pressure worries. Test to make sure the loads are not squibby, though.

That white jug was used for the first few months of production - but rapidly was replaced with the Red background and white pistol cartridge image.

GJ

-

1

1

-

2

2

-

-

IMR Red was a very versatile powder. I used it in cowboy cartridge loads and target shotshell loads in 12 gauge. Burned clean. I'm down to my last pound. Was sad when production was stopped 4 years ago.

And to answer your second question, yes, I have used a LOT of Red Dot for cowboy shooting, very similar to IMR Red loads.

good luck, GJ

-

1

1

-

1

1

-

-

A double feed CAN be caused by tentative stroking of the slide. Kind of like a hesitation step. 97s do like to be run "with authority" - when you stroke the slide, go ALL the way back and then forward.

But, sounds like you are close to having exactly the right length of spring now. GJ

-

First thing you probably need to do to get the last shell in a Model 97's mag to feed, would be a thorough cleaning of the mag spring, tube and follower, then a coating of a DRY lube on the all those parts. EEXOX or Boeing T9 sprays are great. Use just enough to cover the surface - not "dripping wet." Most other lubes do not dry and the wet nature of the lube attracts dust and turns gummy. While in there, make sure the follower can slide easily and completely through the full length of the tube. Dents or spots where the mag tube has been squeezed out of round are bad news, but can be rounded back out with a "barrel dent raiser". Really neglected tubes may not clean up with a 10 gauge shotgun brush and may need to be scrubbed a lot to remove rust, or honed with a "flexible balls" type bore hone.

Second thing that is important for success with the "last round" feeding is a strong enough and long enough spring. Old springs get weak. Both your original Winchester made springs are probably worn out, so it's not worth worrying about them. The "6-shot kit" springs can be right on the border line of being too short. A 12 gauge mag spring is kind of a universal-fit item across most models, so order a couple of high-quality springs made for (I prefer) a Remington 870 pump. Then, open up the magazine front plug and put in the follower and spring, until you are sure the follower has come all the way to the rear of the tube - showing the follower surface in the mag tube opening the in receiver opening, flush with the inner (rear) surface of the frame. Uncompressed, you will probably need 6" of spring length dangling out the front of the tube at this step, Snip off the extra spring with sharp side cutters.

Assemble mag tube and test load with 6 dummy rounds (or if loading live rounds, do this in a safe area). Commonly, the 6th round will be tough or impossible to slide in. In that case, trim one turn of the spring front end and try again until 6 shells fit in a tube.

Once you can fit 6 rounds in comfortably, then try cycling a full tube of them them through the gun, watching the loading port area to see that each one pops backward with the base of each hull almost perfectly flush with the receiver wall. If last one is not coming out to flush, try poking it forward and slightly sideways to see if there is a burr or misalignment between the tube and the front of the receiver which catches the round. Test, examine the fit, and correct the misfits.

Work with one gun at a time, until you get to the "happy length and strength" of a spring to let you load 6 in tube, then cycle all through the action. Do not try either STRETCHING or COMPRESSING the spring coils to make a fit. Those things weaken the tension on a spring. If you cut one too short, toss it. They were like $12 a spring last time I ordered some from Wollf.

good luck, GJ

-

3

3

-

2

2

-

-

The phrase is commonly interpreted in local and large matches I've attended as the shooter only has to shoot enough shotshells to engage each target (shot close to).

If two targets of four are taken out with first shot, then two targets (two shots, or even one if closely set) are still to be engaged.

If four rounds are fired to engage the targets but nothing falls, shooter may take the 4 misses and move on. Requiring a shooter to use all shells carried to the line before moving on, will simply encourage shooters to carry very few shotshell reloads.

I like DDD's recommended replacement wording, Clear and covers the bases.

good luck, GJ

-

3

3

-

-

1 hour ago, Nostrum Damus SASS #110702 said:

Not deterred, he finished the match.

Shooter should have a good gunsmith take a look at the lever, lifter arm, lifter and bolt-extractor assembly. All can possibly be damaged with an OOB, with e bent lever being most common.

Shooters need to remember to NEVER try a second stroke of a toggle action's lever if the first stroke will not chamber the next round fully. Do not get in the habit of thinking "but this time I'll slam the lever closed". This will never fix a squib bullet or split case section in the chamber or throat or an oversize cartridge, it will often cause the OOB firing, which can damage gun, shooter and timer operator. Not much chance for improving your situation, lots of chance for doing major damage.

The concept of a firing pin locking system was not in Oliver Winchester's mind when he designed the toggle action of 1860, 66 and 73 rifles.

good luck, GJ

-

3

3

-

1

1

-

-

Yep, those look correctly installed (from what the pics show), and nicely lubed where spring tip meets the lever bosses.

VERIFY that there is about 1/8" clearance between the outside bend of the spring and the cover plate which fits next to it. It is common that the after-market spring tips are made over-length and need to be shortened. IF the tip is too long, THAT creates can put a lot of stress on the lever or lifter arm. As well as making the levering action rough and harder than required.

good luck, GJ

-

One can also use a sharp narrow cold chisel, catch a rough spot on the break surface with the corner of the blade, and drive it CCW with some taps. If nothing exists to catch, then one can drive up a burr with a center punch enough to start working the screw out. Or drill a small hole at the edge of the break surface with a dremel tool and a carbide point to serve as a grabbing spot.

good luck, GJ

-

1

1

-

-

It's going to be soft solder, so it's able to be repaired without the solder on the barrels-to-ribs junctions being softened when the lug is attached.

I'd certainly recommend Briley to do this - all they do is shotgun work, mainly on high-end guns, which an SKB is close to being.

Either them, or Art's Gunshop in Hillsboro MO, who do a LOT of high-end side-by-side and O/U barrel set repairs..... https://artsgunshop.com/contact-us/

Cost is often pretty high on this because it can often require re-rust bluing the barrels after the soldering. If you do not care if the bottom of barrel area is left "de blued" or even just can be cold-blued to get a "fair match" of color, mention this and they may be able to reduce the cost.

good luck, GJ

-

1

1

-

-

Pods have way too much detergent in them for a tumbler container and are expensive. If a pod works, so will a half a teaspoon of much cheaper liquid detergent. Just my informed guess. GJ

-

1

1

-

-

If that is a flat nosed bullet, and you have a round nose shape in the bullet seater die stem, I'd contact RCBS and ask for a flat nose seater stem for the die.

good luck, GJ

-

1

1

-

-

Quote

would make more sense (to me) if you would assign x/y/z axis details.

Gun nomenclature for DIRECTIONS are given in the "standard" orientation of the firearm. As if you are holding close to the back (butt or grip) of the gun, gun upright and pointed down range. For maintenance / gunsmithing, cartesian coordinates are seldom used - most folks have no 3-axis measuring equipment or machine tools to be able to use them.So, let's amplify the shorthand I used, and say, the bevel is made "wider" by extending the bevel surface at the vertical edge window frame to the left. The existing factory angle for the bevel is made shallower - there is no real direction for the angle - you are retaining the same vertex of the angle, and reducing the "included angle" from the surface of the frame to the "hypotenuse" (surface) of the bevel from 60 to 30 degrees - thus no direction involved with "shallower."

Guns past the CNC machining stage are not normally dimensioned in x-y-z cartesian coordinates from some reference point. The directions within guns get described left-right, up-down and forward (down range) and backward or rearward (towards the user). As has been done for a long time, especially by gunsmiths.

I'm an engineer by training and practice, and this "antique" nomenclature for directions, although sometimes clumsy, is very natural if you "put yourself in the shooter's mindset." But, when I write for other shooters and smiths, I will not show cartesian coordinates on anything I cook up. (Guns are close to a rectilinear two-dimensional system if you look closely at how parts are usually designed and operated, since motions are largely axial aligned to some sort of bore, including rotating in a bore, or rotating around pins.)

good luck,, GJ

-

7 hours ago, El Sobrante Kid said:

Do you mean; make it wider side to side, and shallower front to back. Or the opposite; wider front to back, and shallower side to side? Thx

I was talking about changing the angle of slope on the bevel on the left side of the mortise (window) in the frame where the loading gate and carrier meet.

Shallower means the angle has to be altered from fairly steep angle (like, perhaps 60 degrees from the face of the rear surface of the frame's carrier shaft, to more like 30 degrees referenced to the frame face. Thus, shallower angle. Thus, easier for the rim of the cartridge to slide around on the bevel as the carrier starts to rise.

Wider is what results when you make a bevel shallower and leave the vertex of the angle (at the left side of the window) in the same spot. With "included" angle of the bevel going from 60 degrees to 30 degrees, and the opposite side (the frame thickness) staying constant), the hypotenuse of that included angle becomes longer, thus looking at the bevel from where the carrier shaft is, the bevel surface "looks wider."

"Shallow" really can only apply to the angle of the bevel in this example. "Wider" can only apply to the angle's hypotenuse (beveled surface of the cut in the frame). High School Geometry is your friend in working this problem.

good luck, GJ

-

At this point, I'd work the bevel on the left side of window, the blue area I posted a picture of earlier. Make it wider and "shallower". Good luck, you are on the trail now. GJ

-

Nope, aluminum and brass are close to same strength at resisting abrasion. MIGHT remove anodizing, though. If it's got to "stay pretty" - test an old anodized part you don't care about. GJ

-

2

2

-

2

2

-

-

ALWAYS run away from any request to use a "no refunds" payment method. Zelle, Bank Transfers and PP Friends and Family (I call them Fiends) all are giant flags that someone is fishing for your money! Also, any request for gift cards! GJ

-

4

4

-

-

I guess you did open that bevel up! Hope it works well. GJ

-

73s don't need all that much front-of-gate-spoon width. Sure your 60 needs to be wider than factory made it? GJ

-

Think you are having just about the same mechanical catching on the frame of the gun as the rounds are levered up as happens with some 73s and 66s.

The instructions on Pioneer Gunworks for fixing the loading gate mortise bevels appears that it would fix this gun as well.

Hit this link

then open the downloadable instructions: Frame Modification for 1866/73 (Round Alignment Fix)

But you will have to be the one to figure out if this is a good fix for your gun. I've not applied it to a Uberti 1860.

Where cartridges normally jam in most toggle link guns is the rim sits to the right as it ready to be levered up. And that is usually because the bevel on the frame's left side is not gentle enough) to let the cartridge reliably self-center. Comparing your two photos above, one of a 66 and then the next photo of your 1860, I can see the bevel cut in the frame is a very different angle and size.

good luck, GJ

Then the next bevel to check is the one at the TOP of the window (mortise) cut in the frame. Which is covered by the carrier in both of these pictures.

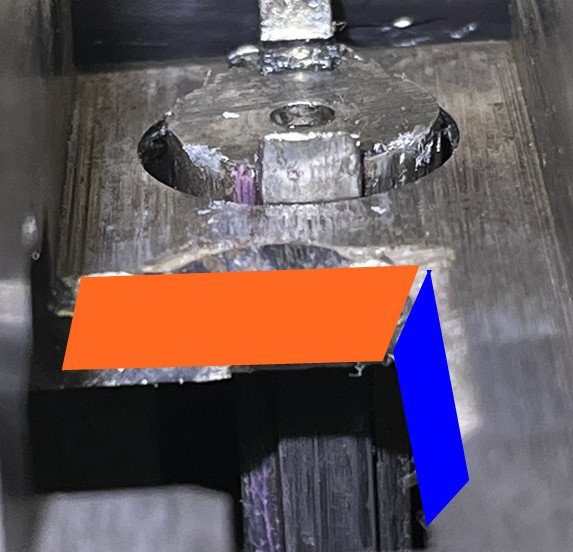

That bevel needs to be cut about like the orange area shown in this next photo:

This "top of window" bevel is REALLY what helps force the cartridge slightly forward as the carrier begins to lift, which keeps the rim from jamming against the back wall of the frame (the point just below where the bolt comes through the frame).

good luck, GJ

-

Basically, lighten springs that are used to resist action opening, perhaps polish the hinge knuckle or the forearm iron contact point a little, look for any obvious drag marks on the action and polish that area.

BUT - Not a lot of single shots are being used in the sport even by buckaroos. I tried to fix one up for SASS, and the young shooter did not like the recoil of a short Win 37 single shot with even VERY light 12 gauge shells. GJ

-

When I work on something like this with hand tools, I use files first to get rough shape (using fine teeth files - usually sets of needle files). Fairly light pressure and lots of attention to making a consistent cut across the face of a section which should end up "planar" (a flat). A sharpie applied before filing tells me where I am "out of flat" after a couple of light strokes.

As things get functional, switch to hard "trigger" stones - either very fine carborundum or hard Arkansas or diamond-coated "stones." Light pressure on those, too. Even for triggers and sears, that usually puts on a "smooth enough" finish for shotgun actions.

If I need super-polish, then out comes the electric die grinder motor (like a Foredom) and Cratex tips - use very carefully. Or some grinding compound on a scrap piece of steel or glass that fits the work.

good luck, GJ

-

1

1

-

Wolff spring kits... wire vs flat springs

in SASS Wire

Posted · Edited by Garrison Joe, SASS #60708

Can you clarify WHICH springs you are wanting to replace? I'm guessing the one you are asking about is the "sear bolt" spring.

With little else to go on, I would favor a wire type spring for "the greatest improvement in function for a smooth, light trigger." (Wolff's claims on their web site)

But, if you wanted to compare how they work in your guns, you could order one or two of the flat springs for the bolt, also, and test how you like the feel - against the wire springs. Since Wolff sells just the individual bolt springs, you would not have to buy a full kit of the main, bolt, base pin and ejector rod springs to just get a flat bolt spring.

good luck, GJ