-

Posts

960 -

Joined

-

Last visited

-

Days Won

1

Savvy Jack last won the day on September 2 2018

Savvy Jack had the most liked content!

About Savvy Jack

- Birthday 11/10/1966

Previous Fields

-

SASS #

76698

Contact Methods

-

Website URL

https://www.44-40wcf.com

Profile Information

-

Gender

Male

-

Location

Hickory, NC

-

Interests

https://www.44-40wcf.com

Recent Profile Visitors

3,133 profile views

Savvy Jack's Achievements

SASS Wire Vet (1/1)

691

Reputation

-

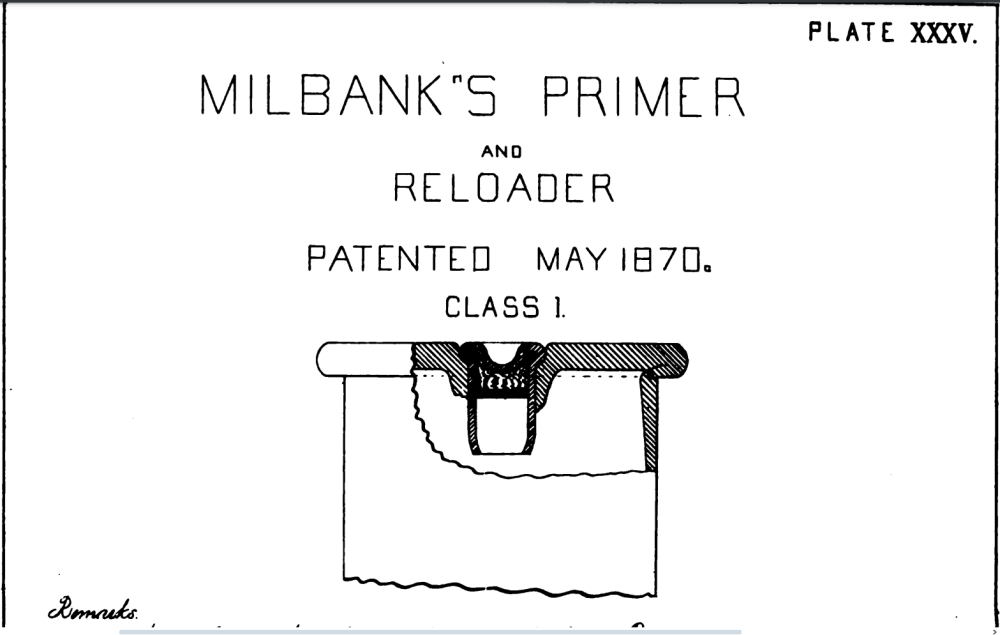

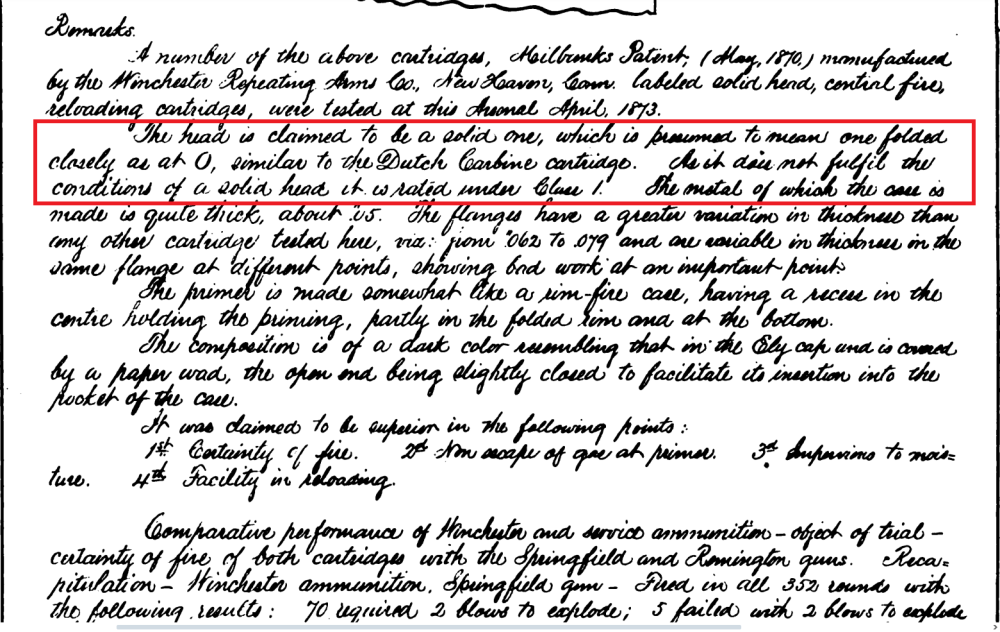

The head [45-70?, 45 Sporting?] is claimed to be a solid one, which is presumed to mean one, folded closely as at 0, similar to the Dutch Carbine cartridge. As it does not fulfill the conditions of a solid head it is rated under Clase 1. For case-head Class ratings, check here

- 1 reply

-

- 3

-

-

Back in January 1919, an article published in "Arms And The Men" about the 44-40 and 45 Colt revolvers and smokeless powder. Ashley Haines writes about his journey with, and the accuracy of both in Colt and S&W revolvers using smokeless powders of the time. Haines never calls the 45 Colt a long colt, and with that....we focus on the 44-40!!! A few items caught my attention, Shooting the 44-40 Colt and 45 Colt at 50 yards with great results Referring to the 44-40 as a rifle cartridge and why Learning that the revolvers shoot best with pistol powder rather than rifle powder Shooting such loads during and after the NOT FOR PISTOL years, unless he has a short memory! Leading when using certain pistol powders It is a long and very good article; The Big Six Shooters

- 1 reply

-

- 3

-

-

New Winchester 44-40 Power Point Ammunition Box Art

Savvy Jack replied to Savvy Jack's topic in SASS Wire Saloon

Got it!! Has been added to the box date code spreadsheet https://docs.google.com/spreadsheets/d/1Jy0pGqWPRx2HOQqufbcnEM1lv6tCWBJsCOB8vLIDOIg/edit#gid=1860800684 -

New Winchester 44-40 Power Point Ammunition Box Art

Savvy Jack replied to Savvy Jack's topic in SASS Wire Saloon

-

New Winchester 44-40 Power Point Ammunition Box Art

Savvy Jack replied to Savvy Jack's topic in SASS Wire Saloon

Guys....all I want is to see photos of the 44-40 power-point box art....... no intensions on purchasing anything -

New Winchester 44-40 Power Point Ammunition Box Art

Savvy Jack replied to Savvy Jack's topic in SASS Wire Saloon

All are insane....lol -

-

Two Weeks

-

That box looks a little older than new....what is the stamp code on the inside of one of the end flaps?

-

I waited 15 "seasons" for 44-40 Winchester brass and JSP bullets, finally gave up years ago. To this day I have NEVER seen any factory 44-40 Winchester or Remington ammunition or components in any store I have ever been in.....LOL

-

The answer to everything use to be "in two weeks", now it is "this spring"!!!

-

44mag--44/40 Convertible Ruger Vaquero Bisley

Savvy Jack replied to Deacon Doug's topic in SASS Wire

However you obtain a 44-40 cylinder, just make sure it is cut properly to utilize .429/.430 bullets. Here is an old link to a 2014 topic about the OMV 44-40 and 44 Mag cylinder. https://www.rugerforum.com/threads/my-blackhawk-44-44-40-convertible.199186/#post-1993822 -

44mag--44/40 Convertible Ruger Vaquero Bisley

Savvy Jack replied to Deacon Doug's topic in SASS Wire

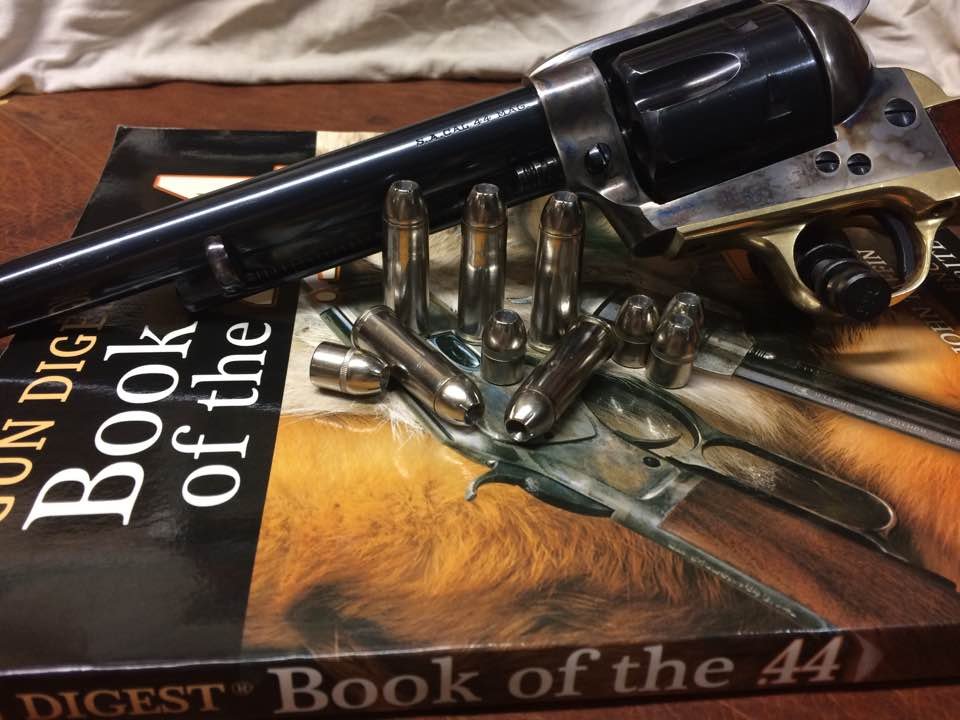

Should be Super Blackhawk and Old Model Vaquero. The Old Model has a larger frame, I believe, as compared to the New Model I have the Uberti Buckhorn 44 Mag revolver with a 44-40 conversion cylinder. As usual, only 44 Mag/44 Special for the same cylinder. The 44-40 is a separate cylinder. If you order a cylinder for it, either-or, you will have "fit-it", or get it "fitted", more than likely. 44 Mag revolver with 44-40 cylinder, loaded with custom HP loads.