-

Posts

11,587 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Everything posted by Garrison Joe, SASS #60708

-

.38 Special in a short stroked 1866 Cimmaron.

Garrison Joe, SASS #60708 replied to Old Irish Shooter's topic in SASS Wire

YES! Slapping forehead. SOME Uberti 1866 were made very early on (1980s) with a short carrier length and chambered for .38 Special ONLY. I know this for certain, as I used to have one in the family and did have to load short rounds to fit that 1.500" carrier block and shaft. Many were imported by Navy Arms. As the story goes, the Italians claimed they designed their 1866 clone early on to take the ammo that the US military issued and that was a very short-nose FMJ slug in a .38 special case. Only after importing them that way for a few years, the US customers demanded a .45 Colt version, and Uberti wised up and stretched the frame design to hold a 1.600" carrier (lifter) block. But, if this IS TRULY a more-modern made gun (this century), it will have a carrier shaft of 1.600", like Uberti builds all their toggle lever guns now. So, it would be VERY unlikely that a 1.490" Overall Length of cartridge is TOO LONG to feed it. So, the OP seems very confused. He stated a 1.490" cartridge would not feed because it is too long. I've already asked that he VERIFY the carrier block or shaft length measurement. I've already asked the OP to verify that he really means that cartridge "won't feed" because it is too long. I've already asked the OP if the gun fails to feed during the beginning of the rearward stroke of the lever (which would likely be a failure to return the second cartridge on the carrier due to TOO SHORT an OAL) or if the gun jams with the cartridge already partially in the chamber near the end of the lever stroke, which could be a VERY poor bullet design that he chose or a fat slug or a dirty/tight chamber or even a ring of brass left in chamber from a separated case. We can't get a clear picture of what the REAL problem is, UNTIL THE OP REPLIES with more information! good luck, GJ -

.38 Special in a short stroked 1866 Cimmaron.

Garrison Joe, SASS #60708 replied to Old Irish Shooter's topic in SASS Wire

You can look down into the carrier and SEE if your load is too short for your toggle link gun. The shortest length that will not jam the carrier with one round cleanly on the carrier and part of another also out on the carrier, is that the rim of the second cartridge has to be on (vertically above) the downward sloping ramp on the front edge of the carrier. If the rim is far enough rearward to be close to or on the FLAT inside the carrier's channel, it will not be able to be pushed back into the mag tube when the carrier rises. This results in a jam of the lever as you begin to bring the lever back toward your face. And the rounds are too long IF the nose of the only cartridge in the carrier is hanging up in the magazine or hitting the frame as you start to close the lever stroke. The shaft of the carrier is 1.600" on modern made Uberti toggle links. It was 1.500" on very early production .38 special only lever guns. If your gun is jamming as you try to finish the chambering portion of the stroke, then it's not due to a short length of the cartridge. It is commonly caused by trying to shoot a poor design of slug for a lever gun, such as a SemiWadCutter (SWC) design. That number he supplied with the gun (1.490") is a very short OAL for an Uberti toggle link gun, unless the carrier has been modified for a very "long" slope of the cartridge return ramp. Or this is a gun that was made way back in the 1980s or so when a shorter carrier was the standard for a .38 special Uberti lever gun. Measure your carrier shaft length (forward/back direction) in the frame. It will give you the MAXIMUM working length of your cartridges. Your loads are "TOO LONG"? At 1.490? Think you mean they are too short, if you have a gun made this century. good luck, GJ -

Rifling will spin a round ball on it's axis (perpendicular to the shaved section of the ball). It has to - the ball is forced into the grooves of the barrel unless it is undersize. How far the ball retains it's spin without beginning to tumble I don't have a clue. Probably at least the first 50 yards, since the ball retains pretty good accuracy that far, IME. And from the experience that Dave Tutt obtained in 1865. good luck, GJ

-

Trail Boss Powder Returns Soon, Hopefully

Garrison Joe, SASS #60708 replied to Rube Burrows's topic in SASS Wire

No, I understand that very clearly. Not running down your past use of TB; you now also have to know that I have never wanted to use it and never will, afaik. So, moving on is the only real alternative anyone has right now. Maybe it gets fixed in the future, I'll bet it does not, for years if ever. GJ -

Yes, HP-38 and Win 231 are the same powder and use the same data. Just two different brand names. Hodgdon used to compete with Winchester powders, now they own the name and oversee the making of all "Winchester" powders. That is why HP-38 name was first created, and now is duplicate and to some folks, confusing year after year. good luck, GJ

-

Cylinder/bore alignment tool

Garrison Joe, SASS #60708 replied to Horace Patootie, SASS #35798's topic in SASS Wire

The professional tool is a revolver range rod. Here's Brownell's selection: https://www.brownells.com/tools-cleaning/gun-tools/action-frame-tools/revolver-range-rods/?sku=080617045 I don't doubt your drill extension is cheaper. I don't doubt Brownell's range rod being accurate enough to spot even minor rotation and axis position problems. I would have my concerns that a big box store part was not made to serve this special high-precision job. good luck, GJ -

Trail Boss Powder Returns Soon, Hopefully

Garrison Joe, SASS #60708 replied to Rube Burrows's topic in SASS Wire

No, I too don''t believe military has use for Trail Boss OR the same family of formulations of flake canister powders we all are missing. And if Trail Boss EVER shows up again, I will be very surprised. It is technically difficult to make it so fluffy, which makes it hard to manufacture (2 plants burned down in 10 years), and expensive. But it is not worth the $250 a bottle that the 300 Blackout shooters are driving the price to. You are getting second hand info here, not first hand directly from Hodgdon management. Instead of spending time asking for it for the next few years and wishing it were around, find a powder that IS being made and grab it before pricing increases. It has already been missing in action for the last couple of years. good luck, GJ -

Generally, most of the powders with a burn rate faster than or same as Unique CAN USUALLY be made to work in cowboy pistol cartridge loads, especially if you stick with the powders intended for handgun cartridges. For example, I have used Bullseye, Red Dot, Clays, Clay Dot, Titegroup, Unique, American Select, Solo 100, e3, WST, Trailboss and some others in 38 special and various 45 caliber pistol cartridges. If you can find a powder, post what you found and most likely someone here has used it like you want to, and can provide you a recipe that is safe and functional. good luck, GJ

-

I'll send you a link to that professionally pressure-tested load. Check your private messages. Since you are new to reloading shotshells, I'd bet you don't have a big stockpile of old shotshell powders made 20 years or so ago. good luck, GJ

-

Of those powders from the 18 year old Lyman handbook, the ones that are still made sometimes are a short list: Unique - usually very hard to find WSF - probably the easiest to find most of the time, but out of stock now HS-6 - in stock at Powder Valley now (but really useful for 7/8 ounce loads or heavier) Blue Dot - very rare to find on a shelf If you might have some TiteGroup (also called High Over All) powder, there's some new tested loading data for a 3/4 ounce 20 gauge load I could point you to from another Internet forum. good luck, GJ

-

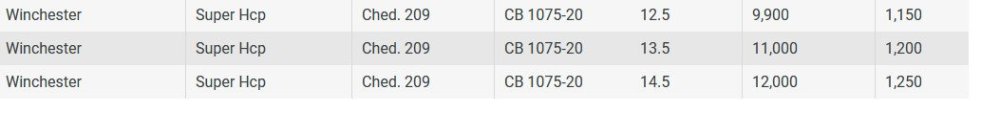

Let me walk you through how to use one of these powder sites. Let's use the Hodgdon site (Hodgdon powders are much more available right now), and let's say you found some newish Winchester AA 20 gauge, 2 3/4" hulls. And Cheddite 209 primers. Ok, let's find a good guess for a load recipe. Open up the Hodgdon link I gave you previously. Pick the Shotgun section of data. In selections, chose 20 gauge and Ched. 209 primer and 2 3/4" Winchester Compression Formed AA hulls Then pick Lead Shot type, 3/4 ounce shot weight (make as light a load as you can), and you see only three powders to choose from (International, PB, and Super Hcp). Gulp, I know that International can not be bought right now due to military demands, and PB hasn't been made for 20 years. Pick the Super Hcp powder. THAT at least you can buy pretty easily. OK, click Get Load Data button. I get 3 recipes. You should too. Here's what I see: ( 3/4 ounce load in Winchester AA 20 gauge 2 3/4" hulls) OK, Winchester is the powder brand, Super Hcp (Handicap) is the powder type, Ched 209 is the Cheddite primer that is easy to buy today, CB1075-20 is a ClayBusters wad that is used in a lot of 20 gauge target type loads, 12.5 on the first row is the weight of powder in grains, next number is the chamber pressure in PSI, and the final number is the velocity in Feet Per Second. Remember I wrote earlier that most loading data is going to be a target or hunting load? Yep, the lightest load here is still scooting along as 1,150 FPS! Anyway, you could try that load, probably have to locate the particular Wad and a 1 pound bottle of Super Handicap powder. Here's the maker of that wad: http://www.claybusterwads.com/index.php/product-by-gauge/by-gauge-20 The neon green wad CB1075-20 is the one in the recipe. Most folks selling shotshell supplies will have it. The powder, Winchester Super Handicap, looks like this: https://www.powdervalley.com/product/winchester-super-handicap/ But, Powder Valley shows both a 1 pound and the 8 pound bottles are out of stock RIGHT NOW. Your job might be to search for a seller that has it in stock! See, told you it could be done, but might require some leg work! 12 gauge loads are easier to find components for, but lots of Out of Stock problems with those right now, too. 2024 is not an easy time to start reloading shotshells. good luck, GJ

-

Shotshell loading is VERY much more specific upon the EXACT components you put together, because in the low-chamber-pressure world of shotshells, things can get dangerous when combined incorrectly. And, besides the low pressure limits, there are the volume requirements. In cartridge loading, air space inside a brass case is not a big deal. In shotshell loading, the components have to stack up such that the combination of the powder, wad, and shot stack to a point that supports the crimp of the hull (unless you make a roll crimp). So, the volume that each component, including what volume the hull holds, is important. It adds the additional requirement that not only does pressure matter, but also the stack volume (height inside the hull of all the components). In loading cartridges, you just match your powder to a bullet weight, and read off what weight of powder you should put in the case. Bingo, you're done, unless you have to jigger the overall length to match what your gun works with, With shotgun shell loading, you load hulls that are made to one exact length - usually 2 3/4" long for the FIRED hull, but about 2.45" long for a 20 gauge shotshell when a folded (star) crimp is placed on the filled shell. So, all the components have to fit in the hull, and the crimp has to fold over onto the top of the shot and get pressed down by the reloading machine to make a firmly closed shotshell without a central hole that shot can leak out. And come out very close to the same 2.45" overall length that the factory made the shotshell to at the factory. So, variations exist in EACH of the components used in shotshells (lack of standardization in the shotshell industry) - * Hull type (different internal volumes, different wall tapers) (none of the different brands are anywhere near as close to other brands as brass cases are) * Primer (sometimes vastly different powder burns due to the power of the primer) (where cartridge primers are much more interchangeable) * Powder (some powder is very dense, some is fluffy, some carries lots of energy and makes high pressures and velocities, other powders carry less energy and makes low pressures and velocities) * Wad (lots of variation in the wad lengths, the amount of cushion space under the shot cup, and wads that fit either a tapered hull wall or a straight hull wall, but usually not both) * Shot (since we use only lead shot in cowboy shooting, not much variation other than the weight of the shot that you put in the hull - more weight means a bigger volume taken up by the shot) All those variations mean there are thousands of good combinations of hull-primer-powder-wad-shot, and probably millions of BAD dangerous or non-working combinations that you do not want to use, including loads that turn out squibby, poofy, or that won't crimp well. Loading manuals and published loading data web sites will show you SOME of the good (tested and safe) load combinations. (And none of the unsafe loads) So, you look through those combinations to pick one that uses the hull, primer, powder name, wad name that you have, and you follow the weights for powder and shot to make a good load. "Absolutely No Substitutions" from your recipe is the wise place to start with when loading shotshells. Other than the Lyman Shotshell loading handbook, there is shotgun data on the Alliant and the Hodgdon powder company sites - here are links to them: http://www.alliantpowder.com/reloaders/index.aspx http://www.hodgdonreloading.com/ Get a copy of the Lyman book because it has GREAT instructions for HOW to load. The recipes you find in there are now at least 18 years old, and the wads and powders, even the primers and hull types, are obsolete. Just like that PB powder you mentioned - has not been made for at least 20 years now, and you wont get to use it ever, most likely! So, look at Alliant or Hodgdon web sites for the best current recipes. That's the good news. Now the bad news. Most of the loads you will find are "factory power" type loads. Useful for hunting or shooting clay targets, not so comfortable for cowboy shooting. But, to practice making some loads, pick a low velocity, light shot load designed for the hull type that you have, and load that just to see how you like loading and if you want to "go to lighter loads yet" - which most cowboys who load eventually get around to making. When you get to that point, we (or your local reloaders) will be around to make some suggestions. But, be aware, most cowboy shooters use 12 gauge guns and shells. You will find less advice available for 20 gauge reloading. And many fewer components like wads. Loading 20 gauge to begin with is kinda tough, compared to 12 gauge. good luck, GJ.

-

I have an very lightly shot Winchester 1894 Angle Eject model in .45 Colt that I'd part with, but I've resisted ever trying hard to sell it as I don't want the buyer to hate me! It's very slow to run the action, as it suffers from the "factory rough action no tuning" philosophy of the builders in the 1990s and beyond. No, don't ruin the gun converting it to 45 Colt. It's fine as it is. GJ

-

S&W Lever rifle?

Garrison Joe, SASS #60708 replied to Gunner Gatlin, SASS 10274L's topic in SASS Wire

9 round mag capacity to make sure they dodge current or possible future hi-capacity-mag laws? Oh, and the MUST-HAVE threaded barrel for a suppressor. Gonna be a great Special Ops gun or a prairie dog sniper. And the $1279 version? It's stainless with a plastic stock/forearm. And a couple of M-lok slots in the forearm. THAT might more sense for throwing in the back of your Soul while off-roading and overlanding..... good luck, GJ -

You mean the last cartridge you have shoved in the loading gate of the gun, which is the FIRST cartridge that you will try to fire. VERY high probability your Uberti has the "loading gate mortise jam" - as about 25% of Uberti rifles have had for the last 15 years at least. If the last cartridge you load which should sit straight inside the carrier block, instead sits cocked crooked with the rim over toward the loading gate, you have the mortise jam. You can temporary prevent this by pushing the last round you load another 1/2" into the carrier block t(pushing with finger or stick through the loading gate), until when you release the round, it sits straight ahead. But the real fix is to put the proper amount of bevel into the frame of the gun. Here's the description of the problem and nice photos of how to fix it. click on the article "Model 66 & 73 frame modification to improve feeding of the first round" half way down this page on the Pioneer Gunworks site: http://www.pioneergunworks.com/technical-info/ I've done many of these to fix the last-round-loaded, first-round-to-fire problems in Uberti rifles and carbines. Your smith may not have noticed this problem if he is accustomed to making sure the cartridges are pushed through the loading gate a long way (half an inch or more), instead of just stopping as soon as the gate snaps shut. good luck, GJ

-

Reloading 45 Colt Seating and Crimp Questions

Garrison Joe, SASS #60708 replied to Doc R Domingo's topic in SASS Wire

To minimize the overworking of .45 Colt cases during sizing, I went to the Redding 2-ring carbide sizer. Lower ring several thousandths larger diameter than the upper ring that sizes the mouth/neck of the case. Unfortunately, I believe they are no longer made. Sigh. Great design and function, I no longer get hardly ANY case splits midway way down the shell. Perhaps folks can convince Redding to make them again? GJ -

Reloading 45 Colt Seating and Crimp Questions

Garrison Joe, SASS #60708 replied to Doc R Domingo's topic in SASS Wire

Absolutely not a SWC bullet. It won't feed reliably in any of my lever guns. Use either a Truncated Cone (TC) or a RNFP (round nose flat point). I run a 200 gr TC bullet with no crimp groove, but cast soft (at 8 Brinnell) so that I can put the OAL where I like it. Usually about 1.550" A crimp as firm as I can without bulging the case right below the crimp. Which with the thick case walls of .45 Colt, means a very firm crimp is obtainable. The firm crimp helps ensure the cleanest possible burn and less blowback gasses. good luck, GJ -

A spray can of CLP, a shotgun chamber brush and a squib rod. For a big match, a .38 and .45 broken case extractor and a shotgun shell checker/sizer. Serious cleaning gear is back at the casa. Either the permanent one or the traveling one. Clean guns most evenings, especially if using a 1911 that gets fouled pretty quickly. GJ

-

I didn't know there was a cartridge named the .45 Vaquero. The .45 Colt revolvers as built can shoot at least 3 commercial and popular wild cat cartridges of course - Colt Schofield Cowboy Special Smallest case capacity of these is the Cowboy .45 Special, and with the very low pressures that the large volume cases suffer from when trying to make a light load, the Special wins out for easiest to load a light load into. Allowable within SASS rules? Must make 400 FPS and 60 PF. So the math says a really dedicated shooter trying to make a .38 Special out of a .45 Colt revolver might try a 130 grain bullet at 461 FPS. Several powders might make that load work; I'd start with Extra Lite or Tite Wad, maybe even Bullseye. I've seen a shooter or two show up whose loads did not MAKE 400 FPS. I was entertained watching the slugs rainbow into the targets 7 yards out. Pards will laugh some. A shooter firing that load will not magically become lightning fast. But, there you go. GJ

-

Realistic Gun Values....

Garrison Joe, SASS #60708 replied to Gunner, SASS #1940's topic in SASS Wire

Swap Meet is Thursday, Feb 29, per the posted schedule (as of today) "6:00 PM – 8:00 PM Swap Meet – Main Tent, Out of Respect for Our Vendors, Please, NO Selling Until 6:00 PM" I'd think you will want to get a "Conventioneers" badge so that you can bring in and sell guns at the event. If you haven't yet done that, contact Sunshine Kay at register@endoftrail.org for details. good luck, GJ -

Realistic Gun Values....

Garrison Joe, SASS #60708 replied to Gunner, SASS #1940's topic in SASS Wire

With EOT coming up in February, a great venue exists in the Swap Meet at EOT for you to sell these personally, and even have several FFLs on the premises to help you with the transfer, if needed. Or, sell directly to one of those dealers in cowboy guns who set up a shop presence all week. Running those guns by a couple of dealers early in the week would at least give you a solid "low end" price at which you could move the gun to a dealer. Then, if the swap meet doesn't sell it, you may still be able to get that price (or slightly lower) at a dealer at the end of the week. With historic guns, a fair price is highly dependent upon how wisely you negotiate the sale, as book values may not even apply. Condition is king, and condition is judged only with guns on the bench "under the scope." good luck, GJ -

Sedalia Dave is right on with his brief comment above. The GROOVE diameter is what folks commonly measure when slugging the barrel. It's real hard to measure the BORE diameter, which the the diameter of the drill and reamer used to cut what remains as the surface of the lands. But any precise caliper or micrometer will measure the GROOVE diameter of a bullet driven down the barrel of a rifle with an even number of lands (or grooves) in the barrel, since the nubs/ribs sticking up on the lead slug that you drive through the barrel are what the measuring device will contact. Those ribs are from the GROOVES in the barrel. So, even though some folks talk about "bore diameter," what really counts is the GROOVE diameter. Because best accuracy often comes from sizing the slugs to 0.001 or 0.002" over groove diameter. It is best to stop talking about bore, and concentrate on speaking about the groove dimensions. (For example, a 30-06 rifle normally has a 0.300" bore, but uses bullets that at least fill the grooves completely, the grooves are usually cut to 0.308", so this means bullets that you buy are 0.308" or slightly larger, especially cast bullets). Unless you want to start making mold modifications (beagling) or bumping up bullets (both are kind of advanced techniques for most SASS shooters), it would be wise to pick a mold that drops bullets in the alloy you will use at 0.380 or 0.381" diameter, for that Uberti made 38-55 rifle. And wise to find a mold that is not cut for gas checks, as most molds you find will be cut to make a gas-check design bullet. The common practice for most long range shooters is to use a gas-check bullet, as it often proves more accurate than a plain base slug. good luck, GJ

-

EOT - RO-I, RO-II and Wild Bunch Classes

Garrison Joe, SASS #60708 replied to Rustler, SASS #33316's topic in SASS Wire

I see on the schedule the Cowboy RO classes are: Tuesday 8:00 AM – 3:00 PM RO I Course – Berger Bullets Building – 1000 Yard Range 8:00 AM – 3:00 PM RO II Course – Bench-Rest Stat House, Opposite Long Range Stages However, the Wild Bunch RO classes are not on the schedule referenced above. A post on the Wild Bunch forum cites the WB RO class starts at 8 AM Wednesday, but does not specify the ending time. Is that one expected to be the same 7 hours as CB classes? Thanks, GJ -

EOT - RO-I, RO-II and Wild Bunch Classes

Garrison Joe, SASS #60708 replied to Rustler, SASS #33316's topic in SASS Wire

What are the timelines for the classes on those days? Do the classes overlap any of the match events that are going on (even the overlaps between say WB match and the Cowboy RO classes)? good luck, GJ